DECHERD, Tenn. - Nissan-Renault's 4-year-old partnership with Germany's Daimler AG ramped up significantly last week with two key moves in North America: the opening of a new Infiniti-Mercedes engine plant in Decherd, and announcement of a jointly owned assembly plant to be built in Mexico.

While the collaboration between the automakers has until now been mostly between the Renault brand and Daimler's Smart brand in Europe, other projects are taking off as the two companies work to expand their businesses using complementary strengths and economies of scale.

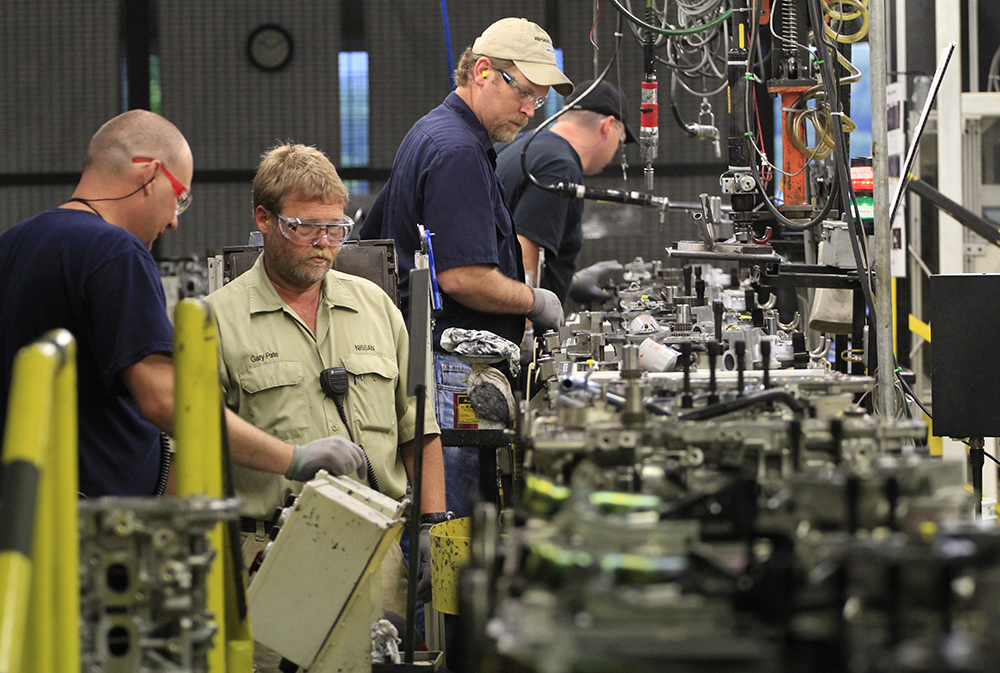

For Middle Tennessee, the engine plant that opened Thursday means 400 new jobs for workers in the Decherd-Winchester-Tullahoma area, adding to the 1,600 that Nissan already employs at its 13-year-old Decherd powertrain facility.

On Friday, Nissan and Daimler said they would share the $1.4 billion cost to build a factory in Aguascalientes, Mexico, to make a pair of new small vehicles - an Infiniti and a Mercedes-Benz - that use the same basic architecture. The facility will be adjacent to a pair of Nissan plants already on the site, and will employ 5,700 people.

"Joint development of compact premium vehicles and joint production in Aguascalientes together represent one of the largest projects between the Renault-Nissan Alliance and Daimler," Nissan CEO Carlos Ghosn said. "It also shows how our collaboration, which began in Europe, has become global in scope."

France's Renault and Japan's Nissan began their own alliance in 1999, with a joint ownership arrangement; Daimler and Renault-Nissan began a more limited partnership in 2010 that until recently primarily involved collaboration on engines and a couple of small vehicles in Europe. The Decherd engine facility is their first partnership in North America.

The Nissan Decherd plant produces engines for Nissan and Infiniti vehicles that are made in Nissan's U.S. vehicle assembly complexes, in Smyrna and Canton, Miss. It also recently began making the electric motors for the Nissan Leaf battery-powered car, which is assembled in Smyrna.

Adjacent to the Nissan Decherd powertrain facility, the new $319 million, 310,000-square-foot Infiniti engine plant began production Thursday with an initial crew of 177 workers, making turbocharged four-cylinder engines that will go into Mercedes-Benz and Infiniti cars worldwide.

The cars that will use the Decherd engines initially will be the Mercedes C250 compact sedans made at the German automaker's only U.S. plant, in Vance, Ala., and Infiniti Q50 sedans that are made in Japan and sold in markets outside North America. The Decherd-built engines will begin to appear in U.S.-bound Q50 models for the 2016 model year, Infiniti officials said.

For now, more than two-thirds of the 162,000 engines the Decherd plant will make annually will go to Mercedes, with the rest going to the Q50.

But the split should even out within the next few years as Infiniti increases its sales worldwide and adds variants of the new four-cylinder engine to other Infiniti models, including sport utility/crossover vehicles, Infiniti Motor Co. Ltd. President Johan de Nysschen said after a startup ceremony Thursday at the plant.

The plant will ramp up to its full capacity of 250,000 engines annually, and full employment of 400, over the next two years, the company said.

Sales of Mercedes-Benz vehicles now far outnumber those of Infiniti, both in the United States and worldwide. In 2013, Infiniti sold 180,000 vehicles worldwide, compared with 1.56 million for Mercedes, including its Smart brand.

In the United States last year, Mercedes sold 343,614 vehicles, compared with Infiniti's 116,455.

Since its inception in 1989, Infiniti had been focused on the U.S. market. But in 2012, Ghosn ordered the move of Infiniti's world headquarters to Hong Kong from Japan, with the goal of focusing on sales in the growing Chinese luxury car sector, as well as other worldwide markets. It wasn't until last year that Nissan introduced the Infiniti brand in the company's home market of Japan.

"We will expand our vehicle portfolio by 60 percent over the next five years," de Nysschen said, adding that the company has a goal of 500,000 worldwide sales within five years.

Last year's sales total was an annual record for Infiniti, even though U.S. sales fell by 2.9 percent in 2013.

Only one Infiniti vehicle is assembled in the U.S. now. It's the QX60 crossover utility vehicle, made in Smyrna on the same line as the Nissan Pathfinder, with which it shares its architecture. Engines for both of those vehicles are made at the Nissan Decherd plant.

Other Infiniti vehicles are imported from Japan, including the Q50 and Q70 sedans and the QX50, QX70 and QX80 sport utilities (formerly the EX35, FX35 and QX56, respectively). The previous generation of the QX56 was made in Canton, but production was moved to Japan with a redesign in 2010.

Nissan and Daimler said Friday that the Infiniti vehicles to be built at the new Aguascalientes plant will begin production in 2017, with the Mercedes versions starting in 2018. The plant is expected to reach full capacity of 300,000 vehicles and 5,700 employment by 2021, the companies said.

"In Aguascalientes, we will take our successful partnership to the next level by combining the skills of our two companies, Daimler and Nissan, in one production plant," said Daimler Chairman Dieter Zetches. "Just over four years after the cooperation was founded, the decision for the new plant in Mexico is a major milestone."

Daimler has a plant in Saltillo, Mexico, that makes trucks and buses, but the Aguascalientes facility will be its first Mexico assembly operation for Mercedes-Benz cars.

There already are two Nissan plants in Aquascalientes. The first, which opened in 1992, now has about 7,000 workers. The second, which opened last year, will have about 3,000 employees when it ramps up to full production, said Nissan manufacturing spokesman Justin Saia.

Nissan's Smyrna complex, its first manufacturing facility outside Japan when it opened in 1983, also has grown over the past couple of years. It has added a separate plant to make batteries for the Leaf, and expanded the main plant's capacity to assemble the Leaf and the compact Rogue crossover, both of which were transferred recently from Japan. There are now nearly 8,000 workers at the Smyrna plant.

Reach G. Chambers Williams III at 615-259-8076 and on Twitter @gchambers3.

Highlights of the new Infiniti engine plant at Decherd:

• The product is a world-class, turbocharged 2.0-liter four-cylinder engine with 200 horsepower, It will initially be used in the Mercedes-Benz C250 sedans built in Vance, Ala., and Infiniti Q50 sedans built in Japan.

• The line now can produce 32 engines an hour, or about one every two minutes; at capacity, it will be able to make 55 an hour, or about one a minute.

• The assembly line is 1,371 feet long - about the length of 4½ football fields. It's 46 percent automated.

• Bulk parts for the engines - blocks, heads and crankshafts - are imported from Europe. The crankshafts come from Spain in raw form, and are meticulously trimmed and polished into precision components.

• Each engine has its own detailed manufacturing history, permanently stored in a computer database, which can be referred to if the engine ever fails. Data include the exact tolerances to which each bolt is tightened.

• More than $3 million was spent on testing equipment for the Quality Control Lab, which has tabletops made of thousands of pounds of granite slabs that are suspended on air to eliminate vibration from the surrounding floor.

• Every worker goes through a two-day session in the Takumi Workshop, where the workers completely disassemble, then reassemble, an engine to learn how every part fits and operates. "Takumi" is a Japanese term for "master craftsman."