View our past VW SUV coverage

DO YOU HAVE WHAT IT TAKES?In 2009, a VW executive summed up the kind of worker the company wants at its Chattanooga plant: Capable, local people who can work together in a team environment to build cars safely and with the highest quality. VW has also indicated the need for:• Training: More highly skilled workers overall and more workers with training in science, technology, engineering and mathematics• Education: The more the better, though college isn't required for production workers• General: Workers who can thrive in a participatory and innovative environment

How do you get a job making the new sport utility vehicle at Volkswagen's Chattanooga assembly plant?

Pay your dues, work hard and keep your fingers crossed.

That's the strategy that two area 20-somethings have used to get inside the plant.

VW will add 1,800 new assembly workers as it gets the SUV under production in late 2016. Competition for jobs was fierce in 2011, when VW filled the first 1,500 slots at the plant from a pool of 85,000 applicants.

This time around, VW spokesman Scott Wilson said the Chattanooga plant will hire purchasing, logistics, engineering and human resources people first and won't start hiring for the production jobs until closer to the start date two years away.

"We're not ready to talk about how to apply," he said.

That hasn't stopped Kyle Hanson, a 25-year-old from Cleveland, Tenn., from getting a head start on employment at the plant.

"The quicker you get hired, the quicker you get bumped up," he predicts.

Hanson got hired this spring by Aerotek Inc., the Hanover, Md.-based contractor whose Chattanooga office supplies the VW plant here with temporary employees. Aerotek officials didn't return calls seeking comment.

Hanson figures the temp job gives him the inside track to get a permanent job with VW as production ramps up.

In the meantime, he's paying his dues. Hanson works four 10-hour shifts each week doing tasks such as installing sideview mirrors, speakers and weatherstripping on VW Passat doors.

"It's pretty physical," he said.

The assembly plant operates around the clock, and workers alternate between the day shift that runs from 6 a.m. to 4:45 p.m., and the night shift from 4:45 p.m. to 6 a.m. Aerotek pays $12 an hour for the day shift, Hanson said, and $13 an hour at night.

Base pay increases to $15 an hour, Hanson said, if you're hired by VW.

Getting hired through Aerotek required passing a battery of tests. Hanson said he had to answer about 100 questions and undergo a physical examination with blood and urine tests and a drug screening. He also had to show how quick he was at physical tasks, how much weight he could push and pull and how much he could lift overhead.

Once he got inside the plant, Hanson learned how VW does things and worked alongside a seasoned employee on 600 to 700 cars before he was released to work solo on the line.

Temporary work can be a route into full-time employment at automobile assembly plants, said Kristin Dziczek of the Center for Automotive Research in Ann Arbor, Mich., a nonprofit organization whose mission is to be an impartial voice for the automotive industry.

"Temporary workers are a pool for the companies to hire from," she said. "They know you show up every day."

More automakers are hiring temp workers, Dziczek said. The number of temps goes up when a new product like VW's SUV is introduced, she said, because the extra employees come in handy as kinks are worked out of the new product line. And they're good to have on hand, Dziczek said, in case the product is a hit and the automaker needs to produce a lot of vehicles.

Community college track

Ben Battles used community college as his route into the VW plant.

Battles, a 20-year-old Missionary Ridge resident, was homeschooled.

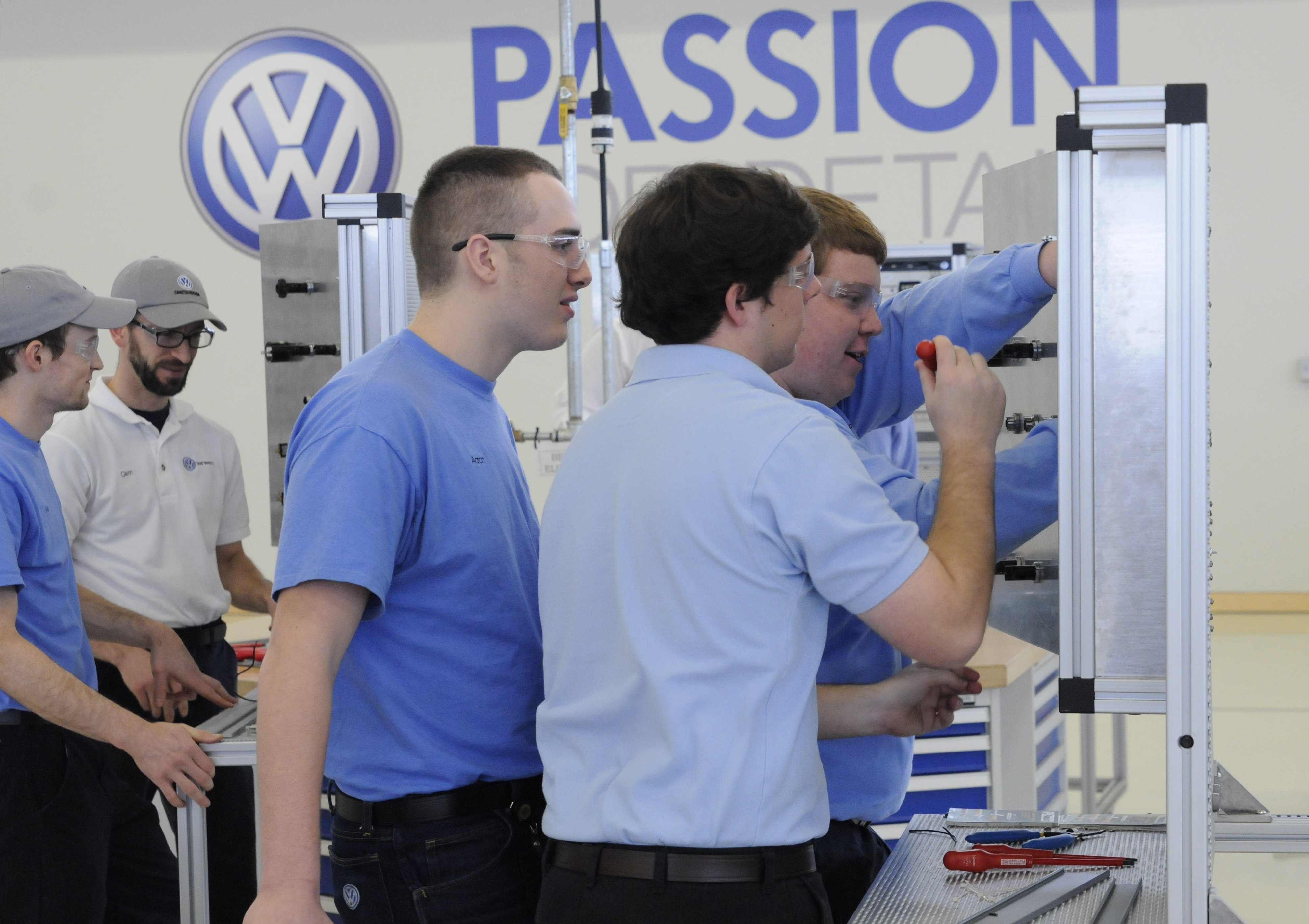

Then he enrolled in the Volkswagen Academy, a training center next to the VW plant that's home to two "Mechatronics" programs taught by Chattanooga State Community College instructors. Mechatronics is a combination of mechanics, electronics and computer-controlled processes. The Volkswagen Academy programs, which are based on German curriculum and Volkswagen standards, combine five semesters of classroom training with four semesters of paid, on-the-job training.

The two mechatronics programs are designed to train technicians in some of the most complex jobs at the assembly plant.

The programs take 12 students each, every year, or a total of 24 students. Since roughly 100 people apply each year, only a quarter of applicants get in the program.

But those who are accepted and complete the three-year program have a good chance of getting a job with VW, college officials say.

"We graduated 12 last year, and all 12 were offered jobs at VW," said Tim McGhee, dean of the Engineering Technology Division at Chattanooga State.

Even if students don't get into the Volkswagen Academy, the Engineering Technology Division offers other courses that can teach skills useful for auto industry work, McGhee said.

Likewise, Georgia Northwestern Technical College has a campus under construction in Ringgold, Ga., that will focus on mechatronics training that would serve people working in a range of industries, college President Pete McDonald said, including auto, flooring or appliance making.

Students' cost for the Volkswagen Academy is minimal, McGhee said, since they're paid a total of about $30,000 during the four on-the-job semesters.

"Love it," Battles said of his experience. The on-the-job training starts at $10 an hour, and increases by $1 a semester. He has worked two semesters inside the plant, and hopes he gets a job helping to build the Passat or the new SUV when graduates in a year.

"I had zero prior experience," Battles said. "I always had a passion for cars, but I never really worked on them."

Contact staff writer Tim Omarzu at tomarzu@timesfreepress.com or twitter.com/TimOmarzu or 423-757-6651.