At Chattanooga's Manufacturing Repair and Overstock, Inc. - or MRO, for short - a growing crew of nearly 30 people receives, inspects and fixes automated industrial parts from across the country.

Because a $1 million machine is no good if it has a bad brain.

Founded in Chattanooga in 2012 by Justin Wilson and Russell Looper - both Atlanta transplants - MRO has grown from two rolling desks in a business incubator to a rapidly-growing small business that has doubled its size every year since it opened.

Wilson and Looper worked in a similar business before coming to Chattanooga.

And on any given day, the company may get a package at the Clay Street MRO campus from anywhere in the country, with a broken machine part, maybe belonging to a fairly new machine or maybe belonging to something built 40 years ago.

But the questions from MRO's clients are the same: Can you fix it? And how much will it cost?

MRO receives between 600 and 800 parts a week, some with requests for repair and some just with requests for a repair quote. The repair shop has fixed everything from giant bakery ovens to giant coffee roasters to machines that make brake pads.

A lot of the staff members have specific skills - some are especially good at electronics, some are good at diagnosing problems.

Items received are logged into the books and given an MRO tag, and the staff can monitor progress so the thousands of pieces don't get mixed up.

Then, when repairs are completed, once-broken pieces are stuffed back into shipping packages and sent back home, whether that's Oregon, Kentucky or just across town.

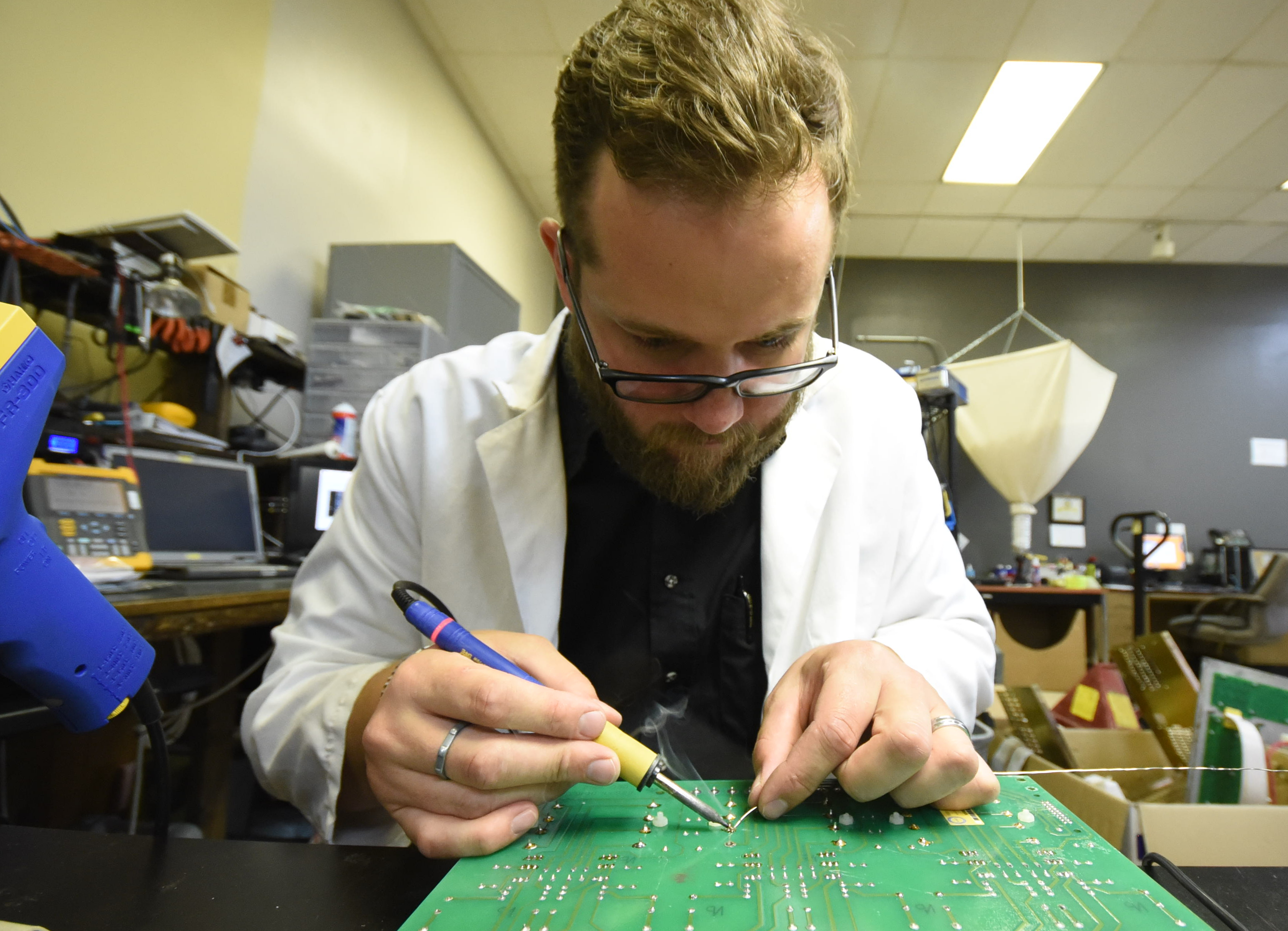

Soldering a busted circuit board with a few bad capacitors is typically a lot cheaper than buying a whole new machine, or even a totally new part, if you can even find one.

Step 1 - At Manufacturing Repair & Overstock, employee Eric Clark logs in a printed circuit board for evaluation and repair.

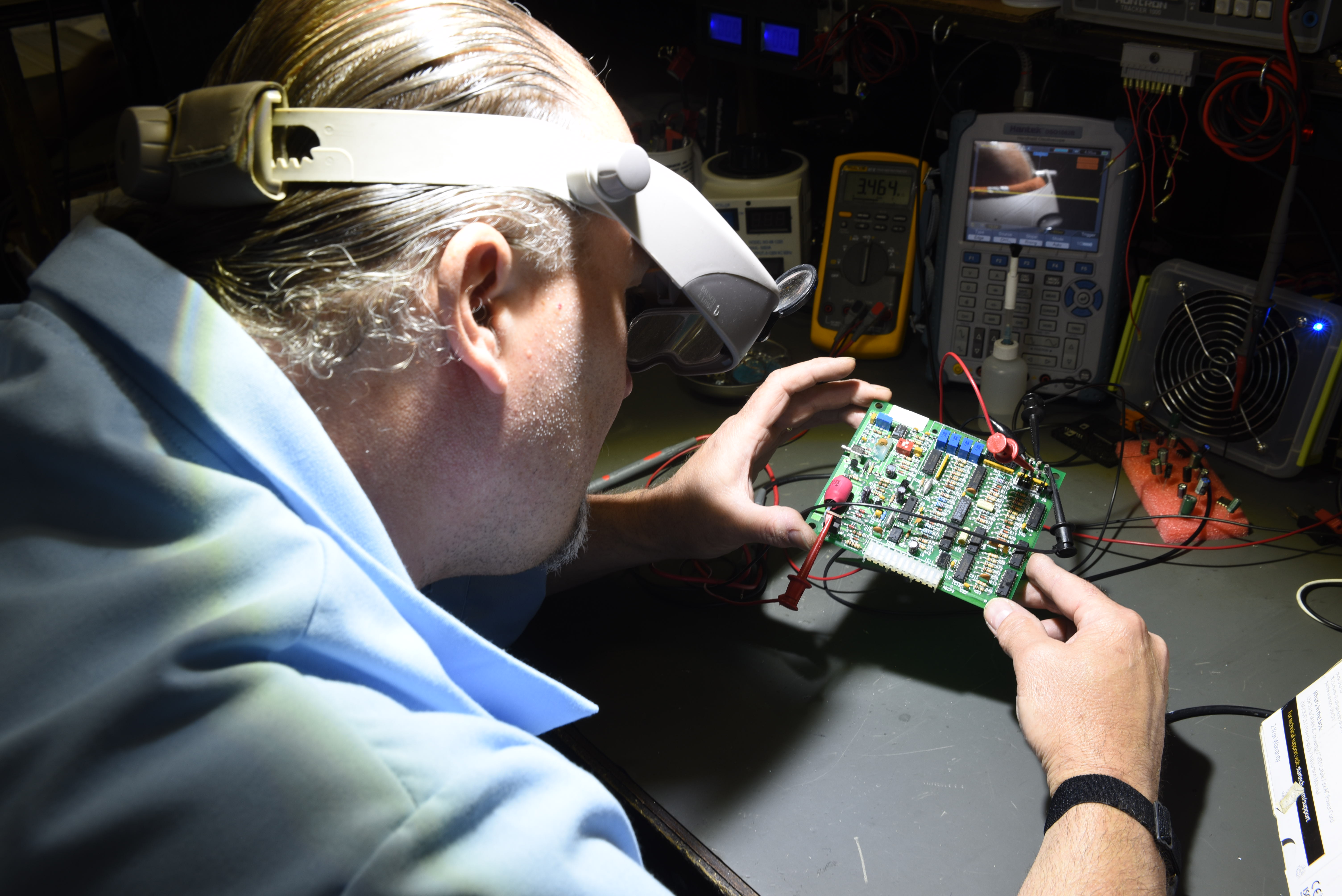

Step 2 - Augustus (Gus) Shipp evaluates electronic equipment before repairs can be done.

Step 3 - Derrick Johnson gathers electronic parts for the job in the parts department.

Step 4 - Henry Robinson sprays depressor on a circuit board, then rinses the unit in a sink to prepare it for repair.

Step 5 - Kyle R. Kuffrey does the repair on a solders it at his work station.

Step 6 - David Northrup does the final inspection on a circuit board following the repair.

Step 7 - Denise Webber prepares a circuit board for shipping at his station using bubble wrap.