Not too long ago, Chattanooga was known as the "Dynamo of Dixie." The year was 1914 and Chattanooga's industrial boom drew national attention. American Lava Company CEO Paul Kruesi penned the dynamo moniker to describe the city's explosive business ecosystem.

Fast forward 100 years and a new boom - 3D printing - promises to shape Chattanooga's future.

"Chattanooga is already turning into a hub for 3D printing," says Graham Bredemeyer, Principal Consultant of Reality Additive Manufacturing Partners. The largest companies in the industry recognize Bredemeyer, who became interested in 3D printing in high school, as an expert in the field.

More Info

Is 3D printing right for your manufacturing company?Find out at this free, interactive event. Lunch included. Seating limited. RSVP to (423) 756-4369 or hashley@chattanoogachamber.comLocation: INCubator, 100 Cherokee Blvd. Chattanooga, TN 37405.Itinerary › 9:00 a.m. Registration and Vendor Expo› 10:00 a.m. Welcome› 10:20 a.m. State of the Industry Address› Noon. Lunch and Vendor Expo› 1:00 p.m. Panel Discussion – Astec Industries, Newcomb Spring of Tennessee, Variable, Inc.› 1:45 p.m. Panel Discussion – 3D Ops, Branch Technology, Feetz› 2:30 p.m. Panel Discussion – ModernTech, NovaCopy› 3:15 p.m. Education & Training Resources› 3:30 p.m. Vendor Expo and 3D Printing Tour – Branch Technology, Feetz, Variable, Inc.Sponsored by INCubator, ModernTech and NovaCopy

Experts hail 3-D printing, a popular term for additive manufacturing, as a next-generation production method. A 2014 Wohlers Report projects the 3D printing industry will exceed $20 billion in worldwide revenue by 2020. Cities all over the world race to secure a position as the hub of this emerging industry, but Chattanooga has a real shot at it.

"The idea that other places in the country are more of a hub for additive manufacturing is a bit of a misconception," he says. "While they may have a greater quantity of companies and people focused on additive, I don't think they have the meat on their bones that we have here in Chattanooga. The level of talent we have is extremely high."

Bredemeyer moved to Chattanooga as a key coordinator for The Company Lab's 2014 GIGTANK, the country's first 3D printing accelerator. GIGTANK drew tech startups Feetz and Branch Technology to Chattanooga in 2014 Feetz participated in the accelerator and Branch Technology attended Demo Day GIGTANK's finale, where accelerator participants deliver pitches to potential investors. Since then, both companies set up shop in the Chattanooga Chamber's INCubator, a startup support program which happens to be located in the same building where Kruesi declared Chattanooga's "dynamo" status decades ago.

Digital cobbler Feetz, founded by Silicon Valley veteran Lucy Beard, works to produce shoes created almost exclusively by 3D printing. Previous limitations on materials and printing processes have thus far restricted 3D printing technology to creating mostly product prototypes and manufacturing molds, but Feetz is pushing the boundaries of what the technology can do.

"Material science in 3D printing has advanced to the point where it's viable to produce durable goods in some sectors," Beard says. "Feetz works with the best companies in the world to develop proprietary blends of footwear materials that meet industry standards expected in flexibility and durability."

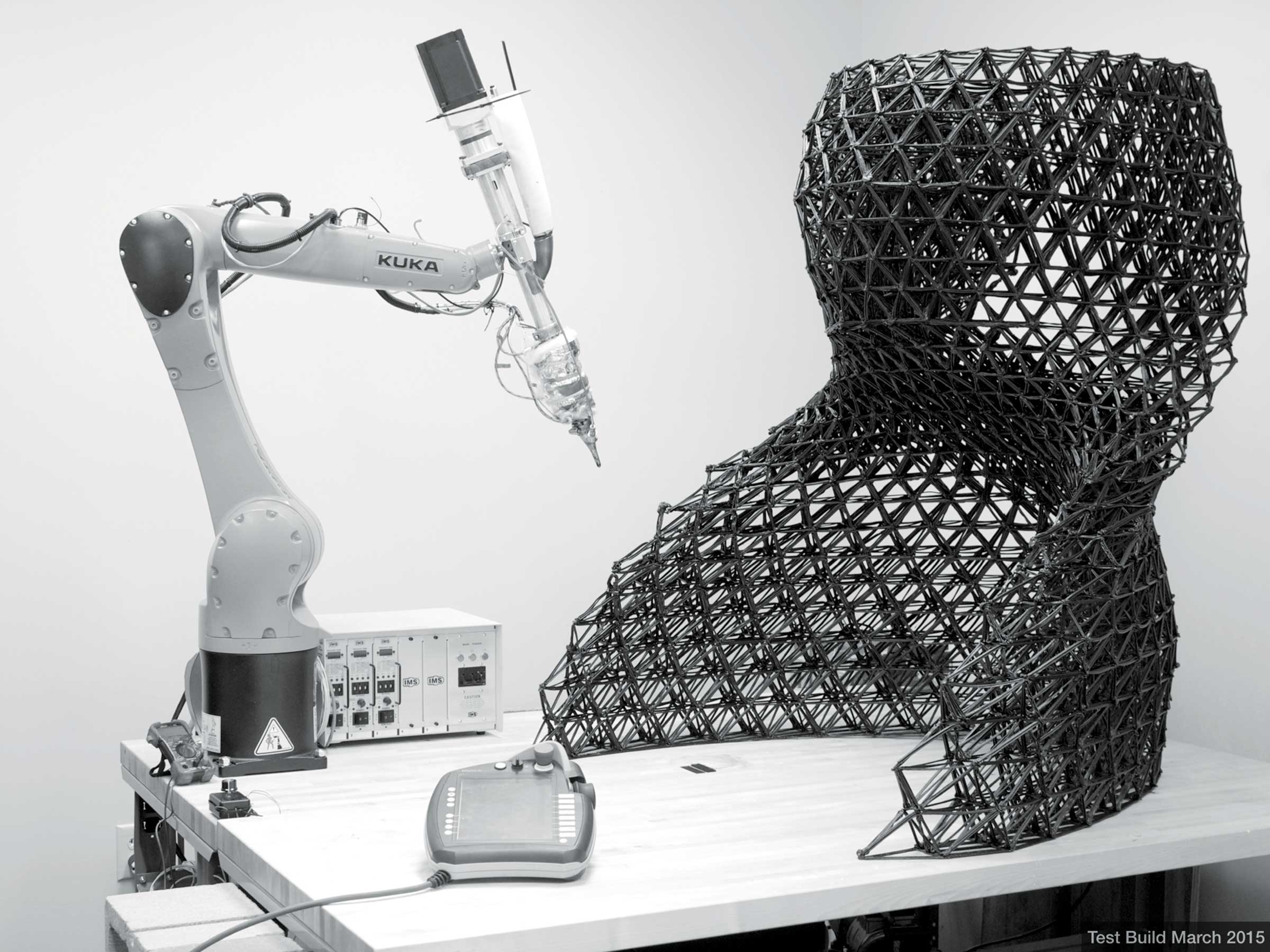

Platt Boyd founded Branch Technology, which operates the world's largest 3D printing robot. An architect with 15 years of experience, Boyd left a successful partnership in an Alabama firm last year to found Branch based on the untapped potential of 3D printing in commercial construction. He designed a composite assembly consisting of a lightweight, 3D printed frame with spray foam on one side and concrete on the other, a free-form building material allowing for ultimate creativity.

"I love it here," says Boyd, who participated in GIGTANK 2015. "Chattanooga is rocket fuel for a 3D printing startup."

Startups don't hold a monopoly on additive manufacturing. Established Chattanooga manufacturers like Astec Industries and Newcomb Springs, as well as several others, have taken the 3D plunge. What all these companies have in common is they took a risk on incorporating the new technology. Bredemeyer and local additive experts, including Branch Technology and Feetz, will discuss the advantages of additive manufacturing at a free seminar Aug. 21: 3D Printing: Beyond the Hype.

"There are many ways to test new technology forms in the additive manufacturng space with consultants and companies that can see if 3D is viable for your existing business," Beard says. "In any business, you have to weigh the costs of introducing new technology but it's not a matter of if, but rather when and how much."