CHATTANOOGA PLANTLocation: Enterprise South industrial parkAnnual production capacity: 170,000 vehiclesModel: PassatSize: 2.5 million square feetStaff: Nearly 3,300 employeesSource: VolkswagenPUEBLA PLANTLocation: Puebla, MexicoAnnual production capacity: 510,000 vehicles; 596,000 enginesModels: Jetta, Beetle, Golf hatchback (early 2014)Size: Nearly 10 million square feetStaff: About 14,000 employeesSource: VolkswagenMexican-Built by the numbers2.88 millionMexico auto production in 2012, up 12.8 percent over 20112.35 millionMexican auto exports in 2012, up 9.9 percent63.9 percentShare of new autos produced in Mexico that went to the U.S.Source: Mexico Auto Industry Association

Hundreds of auto industry people from the South met in Chattanooga recently, and much of the talk wasn't about the region but instead Mexico.

As Volkswagen's Chattanooga plant makes a business case to assemble new products -- such as a potential sport utility vehicle -- officials inside and outside VW are keeping a sharp eye on activities south of the U.S. border.

"The caution I'll offer the region is Mexico," said Jay Baron, chief executive of the Center for Automotive Research, a Michigan entity that focuses on industry trends.

While Tennessee and Chattanooga officials have cited landing VW's $1 billion auto plant, the German car company over the past couple of years has invested or announced plans to plow $1.85 billion more into Mexico.

Earlier this year, VW opened its 100th plant worldwide in Mexico -- a factory producing engines for the Chattanooga-made Passat among other vehicles.

Also, Mexico won a $1.3 billion assembly plant for VW luxury sibling Audi that's going up and slated to open in 2016. That plant is believed to be a direct competitor to Chattanooga for the SUV that VW may develop to better compete in that segment in the U.S.

Jonathan Browning, Volkswagen Group of America's chief executive, said the aim is to have "significant local content" inside the vehicle if it's built, which means the SUV would have most of its parts sourced from suppliers in North America, including from VW's already extensive Mexican presence.

"For our core portfolio, it's important to source those vehicles [in North America] ... and take the foreign exchange rate out of the business equation," he said.

Nissan, General Motors, Ford, Honda and other carmakers also are heavily invested in Mexico.

Mexico is already the fourth biggest exporter of vehicles in the world, and an estimated one of every 10 vehicles sold in the U.S. was produced in Mexico. Its auto output and exports have almost doubled from 2009 levels. Its auto factories produced 2.88 million last year.

Nissan, with an assembly plant in Smyrna, Tenn., and an engine factory in Decherd, Tenn., is building a $2 billion plant in Mexico, which will be its third in that country.

VW has a long history of production in Mexico, going back to the mid-1960s. Its Puebla plant southeast of Mexico City is the country's largest, according to VW. The plant assembles the Jetta and Beetle, and it has nearly 14,000 employees.

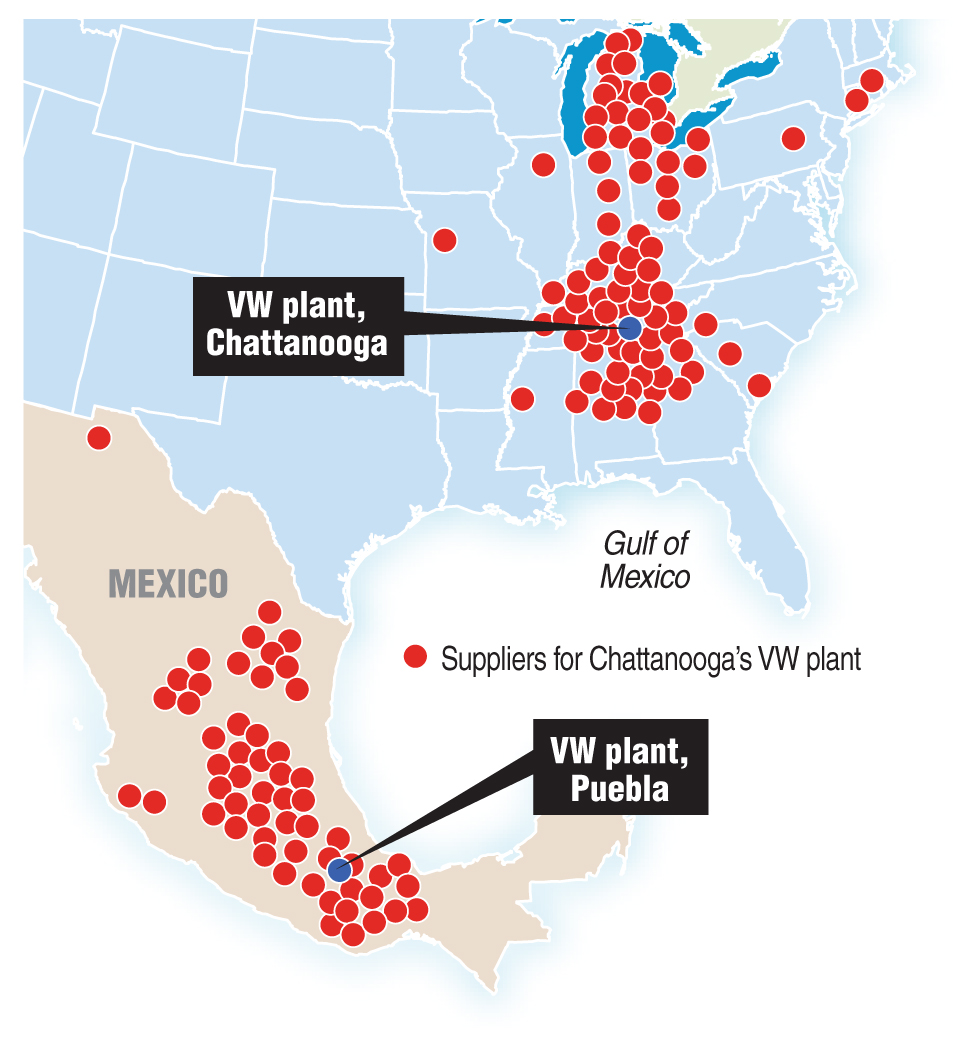

Mexico has a vast supplier network, which is seen more and more as a key for VW and other auto companies, and it offers lower wages than plants in the U.S.

Wages, union

Wages in Mexico for assembly-line workers begin at $40 a day, according to The Wall Street Journal.

In Chattanooga, a new VW assembly-line worker earns $15-an-hour, or $120 a day based on an 8-hour shift.

Some of the VW workers at the Puebla plant belong to a union, an issue that has become front and center recently at the Chattanooga factory.

Horst Neumann, VW's board member in charge of human resources, said last month that it may release a plan for a European-style works council for Chattanooga in May or June, an action that would require a union in accordance with U.S. labor law, experts say. Neumann said talks with a union, presumably the United Auto Workers, could begin in the second half of the year, according to VW.

UAW President Bob King has said that he's "pleased that Volkswagen, known globally for its system of cooperation with unions and works councils, has an open mind about letting the employees in Chattanooga also be a part of the global VW system of co-determination."

But, Tennessee Gov. Bill Haslam and others have expressed concerns that unionizing the Chattanooga plant could hurt future investment and productivity.

He said last week during a tour of the Mars Inc. plant expansion in Cleveland, Tenn., that he has expressed his concerns to VW.

Haslam said the Saturn and Nissan auto assembly plants in Tennessee have had different results. General Motors' Saturn product was discontinued and the Spring Hill plant, which is represented by the UAW, only recently started assembling vehicles again. Nissan's Smyrna plant, which has fought off unionizing efforts, has continued to grow and add production, most recently the all-electric Leaf.

Supplier network

U.S. auto industry experts and Tennessee and Chattanooga economic developers see the continued development of the region's auto supplier network as a way to increase competitiveness.

Bill Hagerty, Tennessee's economic and community development chief, said the state is working with VW and Nissan in a effort to attract more suppliers. The aim, he said, is to reduce the delivered cost of an auto off the assembly line.

"Our goal is to concentrate more suppliers right here and create a logistical advantage that will make Tennessee even more attractive," Hagerty said.

He said the state is trying to tell Tennessee's story to business executives that it not only has a favorable business and tax environment, right-to-work status and good highways, but it's balance sheet is in order.

"When [Gov. Bill Haslam] and I can sit across the table from a CEO... the balance sheet aspect has been a closer to us," Hagerty said. "They don't to want to locate in a state that puts all its fiscal problems on the backs of companies."

Charles Wood, the Chattanooga Area Chamber of Commerce's vice president of economic development, said that attracting more suppliers lowers logistics costs for VW by trimming delivery times.

"That's one big priority for us," he said.

VW already has developed a $21 million supplier park in Chattanooga next to its plant where seven companies employ upward of 500 people, and earth work is going on now to prepare adjacent land for a possible future expansion.

Lowering Trade Barriers

A bigger picture need for Tennessee and the South, officials said, is more and better trade agreements with Europe and South American nations to help the U.S. compete by cutting duties.

Such agreements were one reason VW decided to put the Audi plant, the company's first in North America, in Mexico rather than the U.S., officials have said.

Baron said Mexico has free trade pacts with 44 countries while the U.S. has 19.

Recently, President Barack Obama announced plans to begin negotiations with Europe over trade, an action lauded by Tennessee's two U.S. senators.

"If we lower tariffs, it will make more sense for VW to build plants in the U.S.," said U.S. Sen. Lamar Alexander.

U.S. Sen. Bob Corker said the European trade agreement is important for Chattanooga and the state to help boost German investment in Tennessee.

"If we combine energy prices with a trade agreement, that bodes incredibly well for Chattanooga and the state," he said.

Corker said in a recent op-ed for Bloomberg that a Passat built at Volkswagen's Chattanooga plant faces a 10 percent import duty if exported to Europe. He said that a trade agreement would eliminate these tariffs, reducing costs for the consumer, encouraging further investment in the U.S. and spurring new trade between our economies.

"Greater transparency and regulatory coherence under the agreement would deliver further benefits by cutting our costs and making our businesses more competitive," Corker said.

Clint Brewer, an assistant commissioner with the state's economic development office, said Chattanooga's VW plant has an advantage to gain a new product if its sales will be U.S. focused.

"If you're talking about Central and South America, we've got a tariff disadvantage," he said.

Contact Mike Pare at mpare@timesfreepress.com or 423-757-6318.