Company at a glance

Name: Mueller Co., a subsidiary of Mueller Water Products Inc.History: Founded in 1857 in Decatur, Illinois, Mueller acquired the Chattanooga-based Columbia Iron Works in 1933 and moved the headquarters of Mueller Co. to Chattanooga in 2010Products: Valves, fire hydrants, metering products and systems, leak detection and pipe condition assessment2017 revenues: $826 million2017 net income $123.3 millionLocal operations: 532,00-square-foot plant and office at 1401 Mueller Avenue, just off Amnicola Highway, in Chattanooga, a 109,500-square-foot plant in Cleveland, Tenn., and a 22,000-square foot research and development office downtown at 633 Chestnut Street

Nearly 30 percent of the water pumped to homes and businesses across America is lost to underground leaks along aging pipes and water networks.

But the nation's biggest valve and hydrant maker is helping to plug those leaks using new water hydrants and devices being developed in a technology center that just opened in downtown Chattanooga.

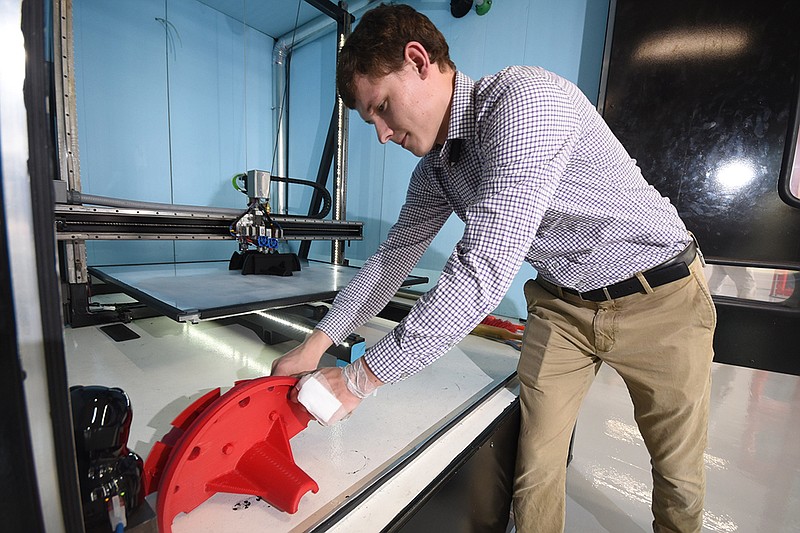

Mueller Water Products, which operates valve and hydrant production plants in Chattanooga and Cleveland and maintains one of its subsidiary headquarters and training facilities in downtown Chattanooga, has converted a former BlueCross BlueShield of Tennessee storage facility downtown into an R&D lab. Within nearly $2 million of testing and development equipment, workers in the new research lab are developing and testing the next generation of water equipment.

"With the advent of the Innovation District and our core offices here downtown as well, we realized we wanted to be here where the thought leaders are and closer to our plants (than the former research facility in Rhode Island)," said Dave Woollums, vice president and general manager for Mueller. "We are developing here the valves and hydrants that will provide much of the key water infrastructure for the future."

Within the 30-employee research facility on Chestnut Street across the street from the Mueller Co., division headquarters in the Republic Center, workers are testing acoustically sensitive valves that can detect early signs of underground leaks. The center also is developing other new products to help utilities find ways to promote better water conservation and quality.

Such equipment is key to improving America's aging water systems. A study of U.S. water utilities released this year by Utah State University found an estimated 82 percent of all cast iron pipe used by utilities is over 50 years old. Pipe breaks have jumped 27 percent in the past six years as aging underground watermains more frequently break and interrupt water delivery.

"We have a huge advantage over other technology companies because we know our customers and their needs," said Paul Gifford, director of research and development for Mueller Water Products. "When you look at the cost of replacing all of our water infrastructure, it is in the trillions of dollars. A lot of the technology we are developing is geared around helping utilities understand their infrastructure and identifying where the problems and needs are with our new equipment to help them extend the life of their existing infrastructure as long as possible."

Mueller has developed new hydrants and valves that can detect underground leaks, or even vulnerable pipes, earlier to avoid major water main breaks.

The new Mueller tech center in Chattanooga is one of two for the company, which traces its roots back more than a century and a half, including 85 years in Chattanooga. Mueller also has an electronics R&D center in Middlebury, Massachusetts.

Hassan Ali, senior vice president of engineering and IT at Mueller, said Chattanooga's innovation district "offers an ecosystem of innovation that has been a great advantage" in cultivating new technology and recruiting talent.

"I'm envious of your 10 gigabit fiber optic connections (offered by EPB), but I know that has been a real advantage for your city," Ali said during a ribbon cutting ceremony for the new technology center this week. "We have recently hired engineers from Auburn, Georgia Tech, the University of Tennessee and other schools and we have never had any problem convincing them to move to Chattanooga."

Chattanooga Mayor Andy Berke, who established the 140-acre downtown Innovation District nearly five years ago, said he wants both new and existing businesses to develop new products and technology in Chattanooga.

"When we started the Innovation District, we wanted it to be more than just a place for startup businesses and entrepreneurs," Berke said. "Chattanooga is a city of creators and much of the innovation that happens occurs in our established companies like Mueller. When hey innovate, that brings true economic development to our city."

Mueller is already expanding its production facility in Chattanooga. The company announced plans last month for a $28 million expansion of its 532,000-square-foot Chattanooga plant at 1401 Mueller Ave., adding 96 more jobs over the next three years.

Mueller currently has 604 employees in Southeast Tennessee with its plants in Chattanooga and Cleveland, and its division headquarters, training facility and R&D facility in downtown Chattanooga.

Mueller acquired the former U.S. Pipe and Foundry in 2005 but sold that company in 2016.

Contact Dave Flessner at dflessner@timesfreepress.com or at 757-6340