A longtime Chattanooga manufacturer is doing business with the gee-whiz venture SpaceX.

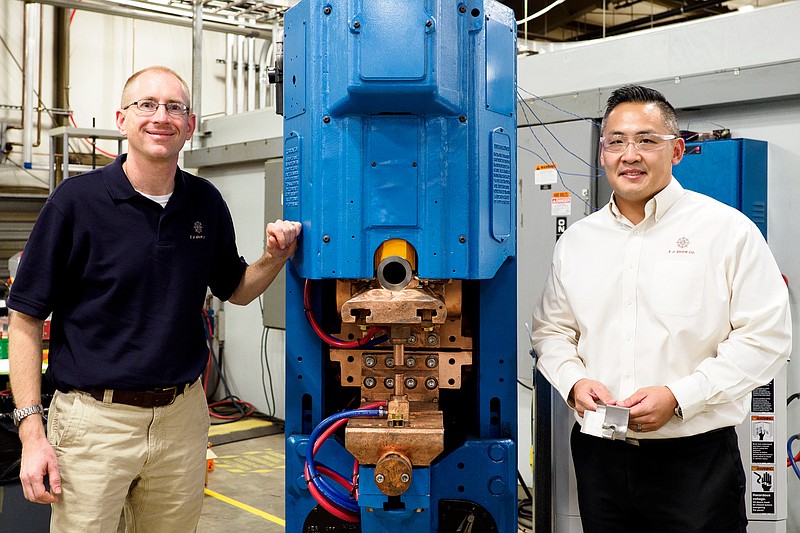

T.J. Snow Co., started in 1963 and operating near Chattanooga Metropolitan Airport, has sold about a half dozen resistance spot welders to SpaceX, which this week along with NASA launched four astronauts to the International Space Station.

Tom Snow, T.J. Snow Co.'s chairman, said SpaceX is using the Chattanooga-made equipment to help build its spacecraft.

"Who would have thought little ole us would be a SpaceX vendor?" he said about the Nowlin Lane business that employs about 90 workers.

Snow said that SpaceX found the local company on the internet a couple of years ago and began buying its resistance spot welders.

"So far we've sold five resistance spot welders to them, with several more now in the quoting stage," he said. "The machines are being shipped to the SpaceX rocket production facilities in California and Texas."

Last Sunday, four astronauts blasted off from Kennedy Space Center in Florida and docked the SpaceX capsule Resilience with the Space Station. It's the first of six commercial astronaut launches NASA has purchased from SpaceX, the aerospace-manufacturing firm founded by inventor and entrepreneur Elon Musk.

Vince Dang, T. J. Snow's applications sales engineer and the company's main point of contact with SpaceX, said that working with the rocket manufacturer is mostly business as usual.

"It does have a lot of confidentiality," he added. "It's a sensitive process to get them to approve the welding samples."

Dang said samples of machine welds go through a specific SpaceX criteria.

"They say it's a good weld and passes the criteria they're looking for," he said. "We move forward with it and then offer the machinery that produces the same type weld."

Dang said there are non-disclosure agreements which note that T.J. Snow Co. can't share pictures of the part it's welding.

"It's rare we see the finished part from them," he said.

Dang said the types of machines it sells can be expensive with the cost easy into six figures for a new one. But, he said, T.J. Snow offers new, used and re-manufactured machines.

Snow said that most of its sales are to companies that fabricate sheet metal components for the automotive industry.

"A lot of times we're speaking with tier-one manufacturers," the company chairman said.

Snow said the business recently designed and built several machines to resistance weld threaded fasteners to structural body parts for the new Ford Bronco.

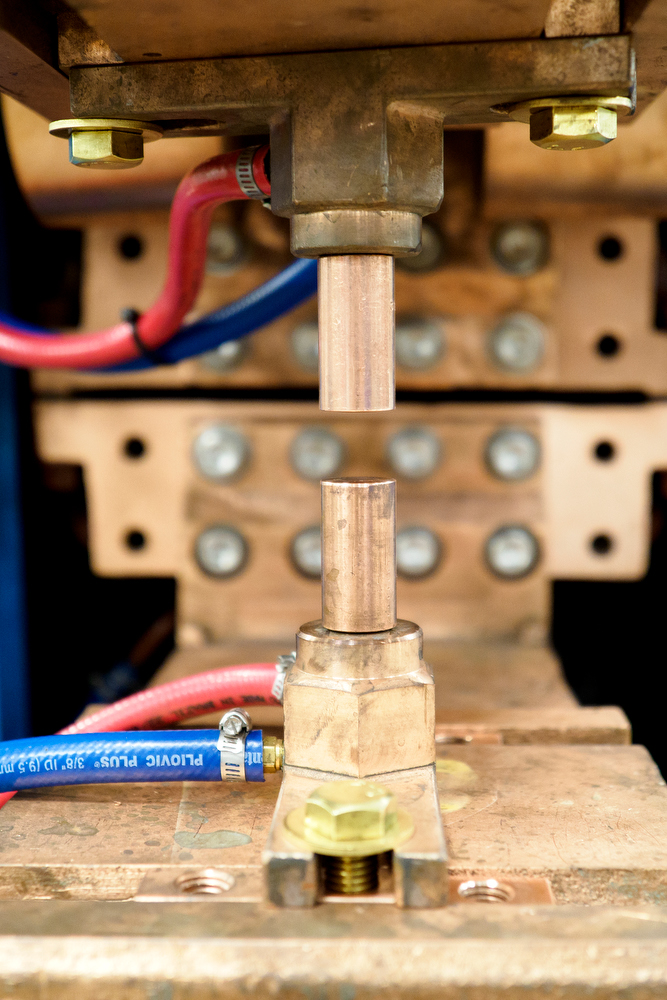

Unlike the more common arc welding process, a resistance spot welder uses no filler metal, he said.

Instead, the spot welding machine uses copper electrodes to clamp the part and pass high amperage where the joint is desired, Snow said. The electrical resistance of the material being welded heats the joint to a molten state and the machine's high pneumatic clamping force forges a weld that is stronger than the parent metal, he said.

Overall, Snow said its business is improving in the wake of the economic lock down early this year due to the coronavirus pandemic.

"It was scary there for a while in the springtime," he said.

Still, revenues are down 15% to 20% from this time last year, Snow said.

Contact Mike Pare at mpare@timesfreepress.com. Follow him on Twitter @MikePareTFP.