A Nokian Tyres' official, speaking at the launch of a key all-season tire last week, used a down-home analogy that likely anyone at its Dayton, Tennessee, production plant would understand.

In order for the Finland-based company to grow in the U.S. and especially in the South and West, "you have to fish where the fish are," said Tommi Heinonen, the company's vice president of sales in North America.

Known worldwide for its winter tires, Nokian is aiming to capture more of the all-season market and a vital strategy in that goal is to grow outside of the nation's snow belt.

"We're expanding our dealer base," Heinonen said during an online roll-out of the Nokian Tyres One tire. "We're going to the South, the Southeast and the Southwest.

Heinonen called the move "a cornerstone of our expansion." Company officials said in late 2019, when it opened its only U.S. plant, that it wants to double global sales within five years.

Nokian's Dayton factory is making the new tire which is aimed at the passenger car market. The plant currently employs 150 people and has a target of growing to 400 workers by 2023.

While hiring isn't based just on one product, it does matter if Nokian is able to expand its business in America.

"It's all about demand from our customers," said Wes Boling, marketing and communications manager for the Dayton plant.

Boling said the tire is one of many the company will continue to develop. Nokian is conducting a long-term ramp-up, he said, adding that more hiring is to take place in 2021.

While the coronavirus pandemic impacted so much of the U.S. economy, the company didn't have to lay off any workers, Boling said. But, Nokian did shut down the plant for several weeks in March and April.

Heinonen said the pandemic hurt the company last year, though he didn't give specific figures.

"It's fair to say the pandemic was hurting everybody in one way or another," he said. "Growth wasn't what we planned or expected it to be."

However, the Nokian official said the company gained market share as last year went on and he termed 2020 "a success story for us."

"We stayed close to our partners, our customers," Heinonen said. "We've seen the value of relationships and are thankful to our loyal customers."

For 2021, he said, Nokian has started strong in terms of booking orders. He said Nokian opened new customers and accounts during the pandemic.

"The outlook for 2021 is very positive," Heinonen said, adding that he believes company growth is expected to be back on track and potentially higher than its early plans.

The Nokian Tyres One goes to core growth for the company, he said.

The new tire is definitely a product fit for such states as Florida and California, Heinonen said.

Hans Dyhrman, Nokians' director of marketing for North America, said the company built "a world-class factory" in Dayton.

"Now it's time to take another major step forward," he said.

Nokian also intends to make the Nokian Tyres One at its other two plants in Finland and Russia.

The tire is expected to be available by the end of the month and together with the Nokian Tyres One HT, launched last year and aimed at the SUV and pickup truck segment, will hit 91% of the North American market, officials said.

Steve Bourassa, the company's North America director of products, said the Nokian Tyres One has better handling, durability, a more even wear and reduces interior and exterior noise.

Also, he said, the tire has added stability for lateral conditions, grip enhancers for soft surfaces such as snow and mud along with hydroplaning resistance for better wet braking and handling.

The tire is equipped with Aramid Armor cord, which he described as a Kevlar-like feature, reducing damages in the side-wall area.

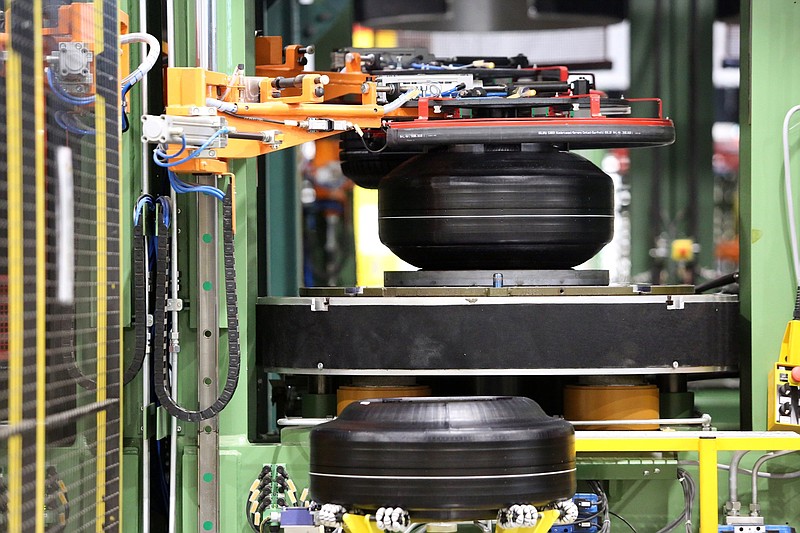

Nokian's Dayton plant is termed by officials as one of the most modern tire factories in the world and the company's largest-ever individual investment at $360 million. The plant also holds Leadership in Energy and Environmental Silver certification, which Nokian officials say is the only tire plant worldwide to hold the designation.

Contact Mike Pare at mpare@timesfreepress.com. Follow him on Twitter @MikePareTFP.