For the electric vehicles slated to come out of Volkswagen's Chattanooga production plant in the future, the focus has to be on the battery, an expert in the technology said Tuesday.

"Everybody wants to make sure they have a vehicle that can go far," said Michael Rademacher, who is overseeing the technical aspects of the high-voltage batteries in North America for VW. "Range anxiety is a real-life fact of electric vehicles right now."

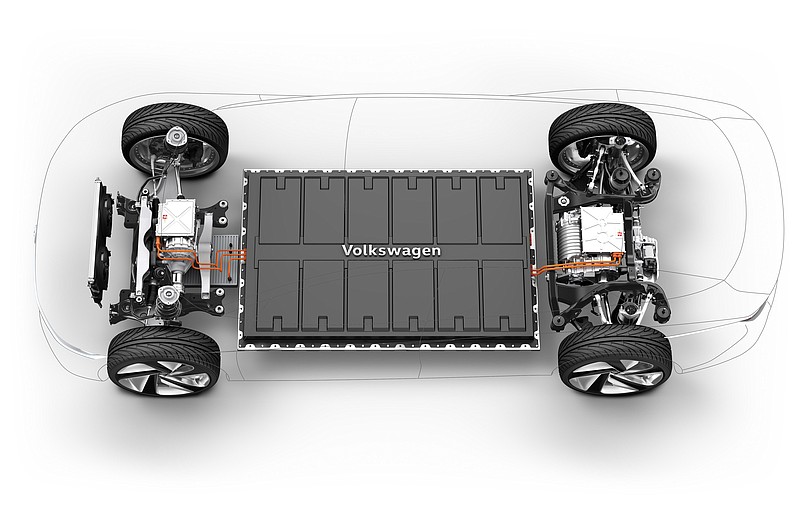

Rademacher, speaking at the kick-off of Chattanooga Engineers Week, said the battery is the key part of the MEB electric platform on which all of the automaker's electric cars will sit.

Volkswagen last month revealed plans to spend $800 to build an electric vehicle facility attached to the company's existing assembly plant in Chattanooga. The carmaker is to create 1,000 more jobs to go with the 3,800 people who already work at the plant to produce an electric SUV by 2022.

Rademacher, who works in Chattanooga, said the batteries are "similar to a skateboard underneath the chassis in a safe position."

"The platform was designed around the battery," he said.

Plans are to take lithium-ion battery cells and put them in a module, Rademacher said. The number will depend on the distance the vehicle will run, he said.

The modules can be placed in a package, which could look like a cylinder such as is done with AA batteries, the VW official said. Or the package could be square or a pouch.

"MEB can accept all of them," Rademacher said, saying the flexibility is needed depending on which supplier is providing them in different parts of the world.

He said that one battery system has some 2,500 components, containing cooling, monitoring and other systems.

But because there's no internal combustion engine and the electric motors sit at the axles, Rademacher said that gives the automaker the ability to produce vehicles with larger wheelbases and more room inside the cabin.

"Our vehicles have a lot of interior space," he said.

Also, there will be no exhaust system or drive shaft in the electric vehicles.

"All of that is gone because of MEB," Rademacher said. "We don't have to worry about that anymore. It's all due to the battery."

Catharina Mette, Volkswagen of America's head of technology communications for the North American Region, said the automaker's e-mobility product line has locations in Chattanooga, Herndon, Virginia, and Belmont, California, and is crucial in helping to bring EVs to the U.S.

"The Chattanooga team specifically is focused on engineering local content and industrializing the new product in the plant," she said.

Mette said that while localization is a pillar in VW's global strategy, there is currently no decision on locating research and development for electric vehicles in the U.S.

Contact Mike Pare at mpare@timesfreepress.com or 423-757-6318. Follow him on Twitter @MikePareTFP.