The shift to assembling electric vehicles is part of what Ilker Subasi calls the fourth generation of the industrial revolution.

"It's a revolution in manufacturing," says the head of the Volkswagen Academy in Chattanooga. "It's about cloud computing, how to process data and customize the cars."

As an $800 million expansion to assemble electric vehicles begins to take shape at Chattanooga's VW plant, the company is ramping up its training efforts.

The entire factory will receive some sort of training when it comes to working in a high-voltage environment, Subasi says, but there will be different types of skill sets for various target groups.

"Whoever touches the car will get different training," Subasi says. "Some it will be two weeks and some a half year. Everybody will get training."

A small group already has been identified as he calls the training effort "a soft ramp-up" with the company aiming for a 2022 start-up for EV production in Chattanooga.

Plans are to send key people to other plants that build electric vehicles so there can be a sharing and exchanging of knowledge, Subasi says.

"With electric vehicles in the building, we want to make sure everyone understands we have different products in the production plant." - Ilker Subasi of Volkswagen Academy about VW workforce training

A plant in East Germany where VW is building the Golf-sized all-electric I.D.3 will be a destination for Chattanooga employees, he says. That factory, too, uses the so-called MEB platform that will underpin the battery-powered SUV that is slated to be assembled in Chattanooga.

As construction on the expansion progresses and new equipment begins to roll into the plant, activities surrounding EV training will accelerate, Subasi says. Safety is paramount, he adds.

"With electric vehicles in the building, we want to make sure everyone understands we have different products in the production plant," Subasi says.

Hiring for training purposes already has begun, with three technical trainers on board and two of those just to work on EVs related to working with high voltage, batteries and robotics, he says.

"I'm still looking for one more," the VW Chattanooga official says. "We need a good, qualified workforce to phase in that exciting investment."

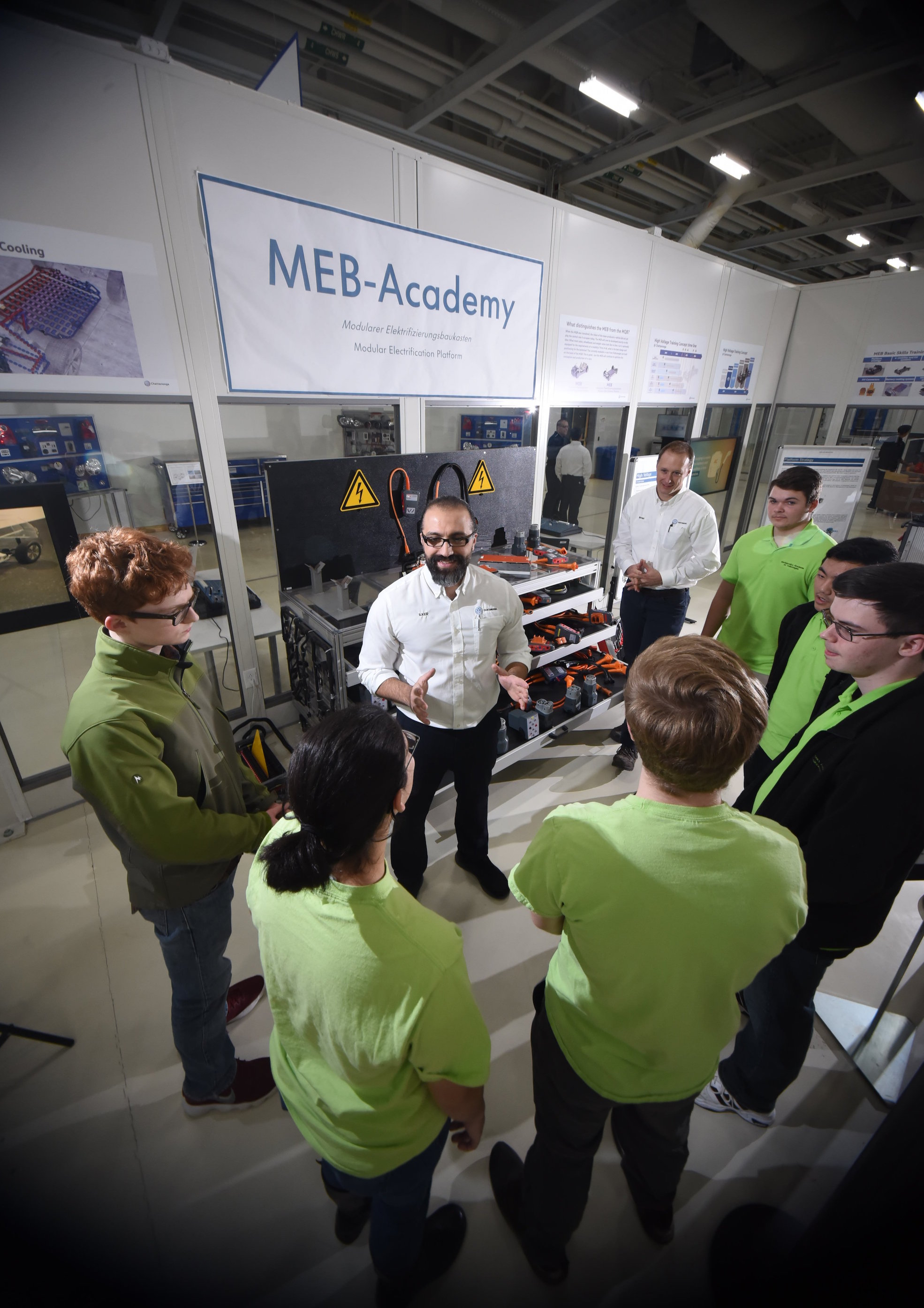

Staff photo by Tim Barber/ Ilker Subasi, center, who heads the Volkswagen Academy at the company's Chattanooga factory, directs his attention to Noah Morais of Notre Dame High School as he talks with students about the new electric vehicle Volkswagen is readying to build. From left are, Morais, Andrea Ramirez, Isaac Guardian, Dylan McGovern, Aaron Bun, Bryson Morris and Brian McCord, high voltage training instructor, back right center. The students were at the academy for an open house involving apprenticeships and other programs.

Staff photo by Tim Barber/ Ilker Subasi, center, who heads the Volkswagen Academy at the company's Chattanooga factory, directs his attention to Noah Morais of Notre Dame High School as he talks with students about the new electric vehicle Volkswagen is readying to build. From left are, Morais, Andrea Ramirez, Isaac Guardian, Dylan McGovern, Aaron Bun, Bryson Morris and Brian McCord, high voltage training instructor, back right center. The students were at the academy for an open house involving apprenticeships and other programs.He terms an electric vehicle "a smartphone on wheels" because of the variety of new technology going into the battery-power autos.

"It's important to have our skill set in place," Subasi says.

Scott Keogh, Volkswagen Group of America's chief executive, says he wants the automaker to take advantage of a new opportunity when it comes to EVs.

"We're fortunate at VW Group that we have a global (MEB) platform with a global scale," he says. "The electric vehicle platform will make millions of cars, and millions of cars is the holy grail. In America, I do see it as a new opportunity."

When it comes to battery power and range, the market response is getting stronger and better and Keogh thinks the timing now is right.

"So it's a game of when can you get the right cost at the right market reaction and get the price that we need," he says.

Read more in this month's EDGE Magazine:

Plugging into opportunity: Five-year electrical apprentice program in Chattanooga grows successLearning and earning: Paid training programs unlock opportunities for workersGet to work: Investments in the Chattanooga area workforce grow along with demand for skilled workers