Raccoon Mountainfast facts• Raccoon Mountain Pumped-Storage Plant has four generating units which until now has dependably produced about 1,652 megawatts a day for TVA.• Construction at Raccoon Mountain began in 1970 and was completed in 1978.• The reservoir constructed at the top of the mountain has 528 acres of water surface that also serves as state-designated wildlife observation area.• The dam at Raccoon Mountain's upper reservoir is 230 feet high and 8,500 feet long. It's the largest rockfill dam ever built by TVA.

TVA's pumped storage facility on Raccoon Mountain hasn't worked since March, the result of four cracked rotors.

Officials with Tennessee Valley Authority said Thursday the problem is a design flaw in the 34-year-old, $310 million plant.

The utility took the entire plant offline as soon as a contractor's alert and its own checks found the rotor cracks in one after another of all four generators there.

But the plant's outage was kept quiet until last Friday, when TVA President and CEO Tom Kilgore told financial analysts that the utility had brought two of its idled coal units back this summer to make up for Raccoon Mountain's lost peak-power generation.

"We brought them back because ... we found cracks in the rotors so we've taken all four of [the pumped storage units] offline," Kilgore said.

John McCormick, TVA senior vice president of river operations, said TVA is not yet making public estimates on a repair cost because the work is being bid out.

"But it absolutely will not cost more than the original plant," he said.

He said TVA hopes to get one generator back up and running temporarily in about 18 to 24 months. The other three are not salvageable even for temporary use, he said.

"We have 900,000 pounds of scrap at this point," McCormick said Thursday.

Eventually the rotors poles and rim of all four units will be replaced, but not until the 2014 and 2015 time frames, according to TVA officials.

"These are parts you can't get at Home Depot," said TVA spokesman Travis Brickey.

Eight feet long, three feet wide, two feet deep and about 7,000 pounds, each of the 24 rotor poles in each generator, as well as the cracked rotor rims, must be custom built. The materials alone will weigh 450 tons, McCormick said.

The German firm that designed the units alerted TVA to check for cracks after rotors in a similar plant in Austria splintered in late 2009. Two other similar plants in Virginia and California are facing similar replacements.

The first unit TVA checked about 18 months ago showed no cracking. But in later months, checks on the other units did show cracks. So TVA looked again at the first unit. On the second look, they found new cracks there as well.

Although all the generators had been running fine, McCormick said TVA chose the safe and conservative route: shutting down the plant's generation.

"If my brake light came on, I would take my car to the repair shop even though it's an inconvenience," McCormick said. "If my brakes failed and I kept driving on it, I could injure myself, passengers in my car, other cars or people on the highway, or instead of losing $100 on a brake job, I may lose my $10,000 car."

That more expensive consequence is what happened in Austria.

When the rotor poles had a "catastrophic failure" there, the shaft of the generator was sheared and the entire unit was mangled, McCormick said.

"We wanted to protect not just our people, but also our asset," he said.

Bridging the gap

TVA has called the pumped-storage plant its "mountaintop marvel."

"Scorned at the outset as a scheme worthy of Rube Goldberg, TVA's pumped-storage generating plant inside Raccoon Mountain became one of the engineering wonders of the Tennessee Valley," states one TVA Web page.

Now the completely green and renewable-energy plant's temporary loss will be a blow.

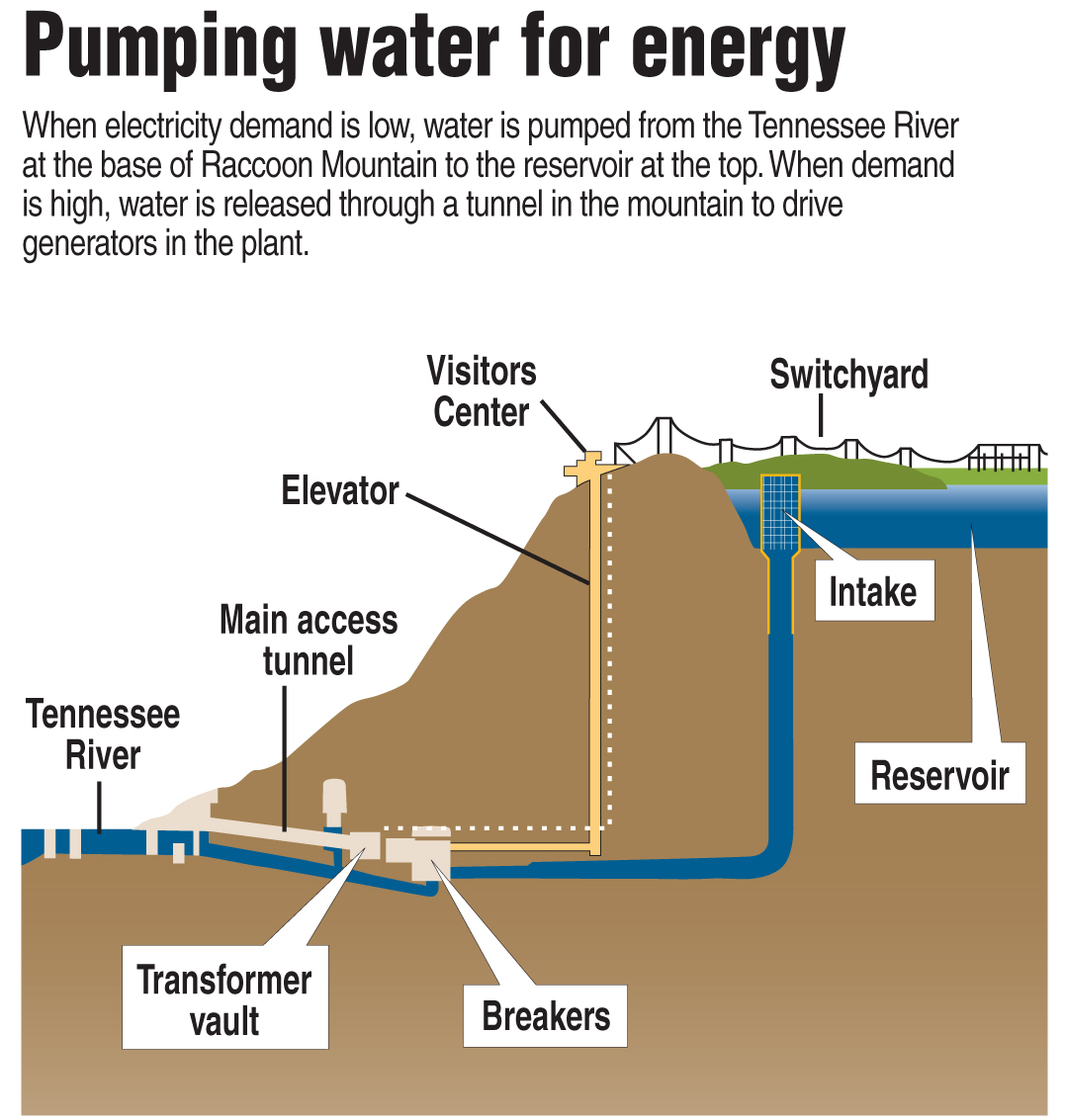

The generators pulled water from the river -- 7 million gallons a minute -- and pumped it up through a cavernous concrete tunnel through the middle of the mountain to fill a large manmade lake above them.

Then with the flip of a switch, that water flowed back down through those generators to make power on its way back to the Tennessee River Gorge below.

Before the cracks were discovered, the plant was used nearly every day, and it served as an important grid balancer for TVA.

Like all hydropower, the electricity at Raccoon Mountain is extremely cheap power to produce.

TVA said the plant's constant push and pull of water made it work like a giant storage battery.

The plant pumped water up the mountain during the hours when consumers were using the least power.

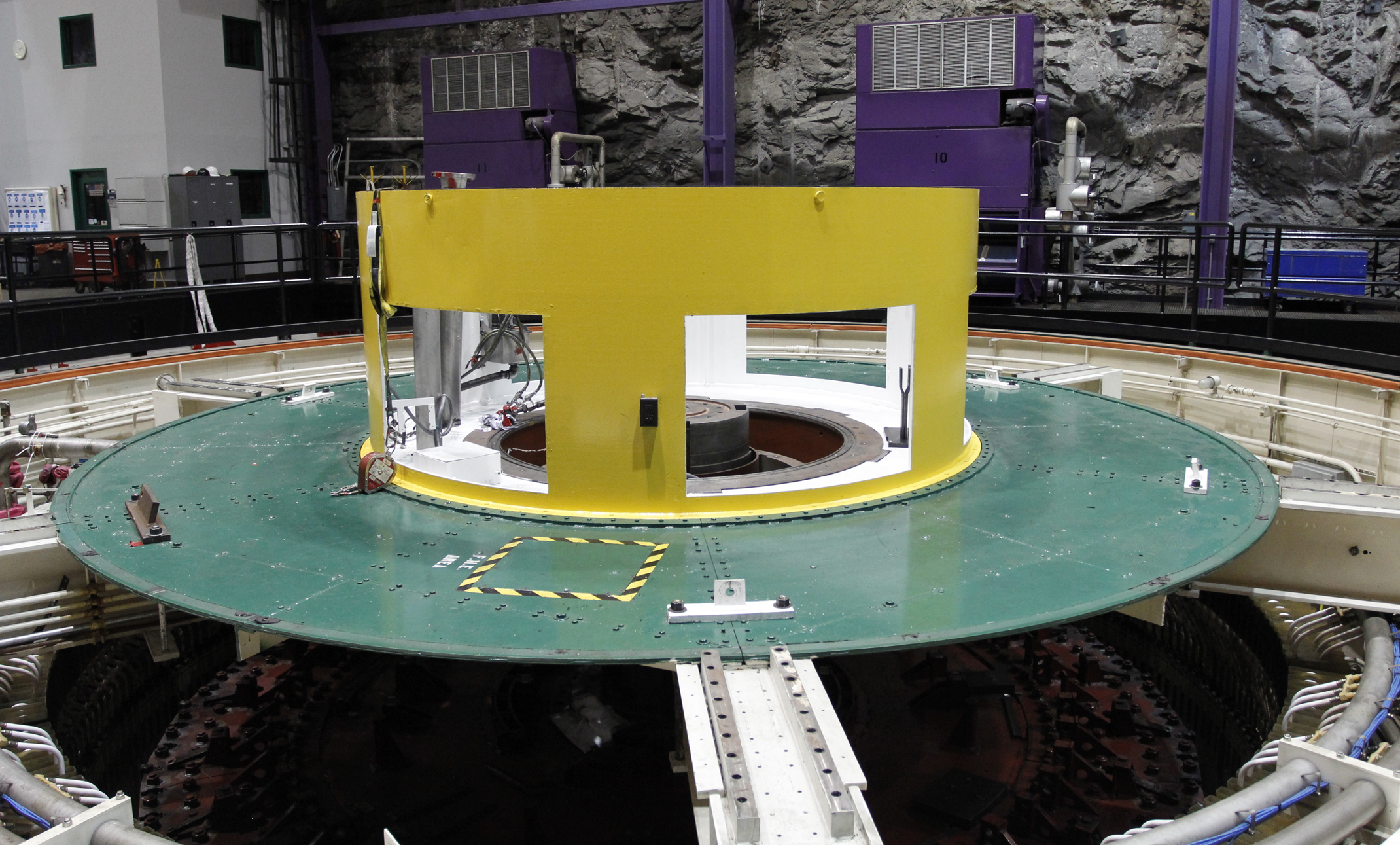

Then when families came home and cranked up the heat or the air conditioning, started supper, turned on the televisions and punched the washing machine button -- TVA would send that water tumbling back down the mountain's 1,000-foot tunnel to stroke four house-sized generators.

The flow of the water spun the turbines to rotate a shaft inside an electromagnetic coil.

The plant provided a "dependable" average of 1,652 megawatts of electricity a day -- enough to power nearly a million homes.

Then the process would be repeated over and over.

It could generate electricity for up to 22 hours before needing to draw water up again for 28 hours to fill the mountaintop reservoir.

McCormick said that if there is a silver lining to TVA's newest cloud, it may be the timing of Raccoon Mountain's outage.

The utility can take advantage of the present low cost of gas and TVA's new gas-fired plants to somewhat balance the added price of more expensive generation or buying power from other utilities to meet the peak demands normally handled by Raccoon Mountain.

Already, TVA board members have been apprised of the outage.

McCormick and Brickey said there may be some discussion about the plant at a full TVA board meeting next week in Knoxville.

On the replacement rotors and rotor rims, TVA will have a new and modernized design that will put less stress on the rotors.

But the rebuilds and replacements will be exacting.

"There's not a whole lot of room inside the plant, so we can't do it all at once," McCormick said. "And that's the challenge."