In the biggest foreign investment ever in Tennessee, a South Korean battery manufacturer plans to charge up the state's economy with a $3.2 billion cathode production facility in Clarksville.

LG Chem, which announced a joint venture with General Motors last year to build a $2.3 billion battery plant in Spring Hill, Tennessee, said Tuesday it will build another multi-billion-dollar factory in Tennessee to produce cathodes to supply the Ultium Cell battery plant being built in Spring Hill to supply the all-electric Cadillac Lyriq.

"The new cathode manufacturing facility in Tennessee brings us one step closer to becoming the world's best battery materials manufacturer and fulfilling our corporate vision to become a top global science company," LG Chem CEO Hak Cheol Shin said in an announcement of the new Tennessee plant. "This site will be the North American manufacturing center of excellence for the cathode supply chain and lead to the creation of many well-paying jobs."

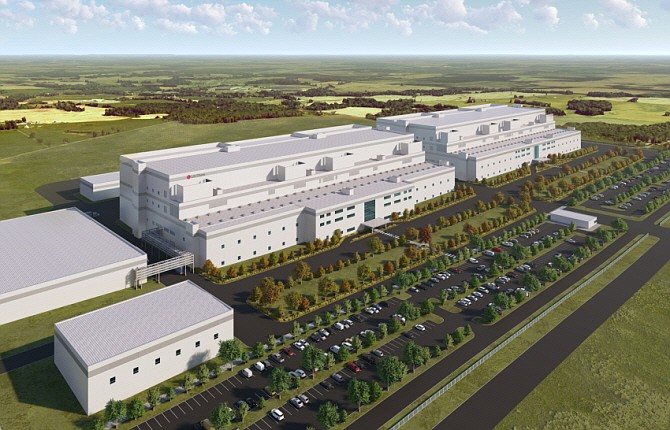

The new plant in Clarksville will be the largest of its kind in the United States, covering 422 acres with a production target of 120,000 tons of cathode material annually by 2027 to power batteries in 1.2 million pure electric vehicles with a range of 310 miles per charge. Construction of the plant will begin in the first quarter of next year with mass production to start in the second half of 2025.

LG Chem currently supplies batteries to Tesla, Ford and Hyundai, and has formed a joint venture with General Motors to create Ultium Cells LLC using a nickel, cobalt, manganese and aluminum (NCMA) chemistry. The Tennessee site is part of LG Chem's strategy to increase its battery materials business including cathode material fourfold by 2027.

The Tennessee plant will feature LG Chem's most advanced production technology including the ability to produce more than 10,000 tons of cathode material per line, the industry's highest. LG Chem said in an announcement that it applied this technology for the first time to its fourth cathode manufacturing site in Cheongju, South Korea, "with much success."

The company recently raised its 2022 revenue outlook to $18.4 billion due, in part, to its new projects from automakers.

The NCMA battery, which is about 90% nickel, allows manufacturers to reduce their reliance on expensive cobalt and reduce their exposure to refining and processing in China, where 75% of the world's cobalt refining capacity and 50% of the lithium processing capacity now occurs, according to Benchmark Mineral Intelligence.

Ultium Cells LLC is a joint venture between General Motors and LG Energy Solution, which is building battery cell factories in Tennessee, Ohio and Michigan. The partnership will receive a $2.5 billion of loan from the Energy Department to build the battery cell factories.

The Inflation Reduction Act will, among other measures, require by next year that at least 40% of the monetary value of critical minerals for batteries be from the United States or an American free-trade partner in order to qualify for U.S. tax credits. That share will rise to 80% in 2027.

Automakers such as Hyundai and Kia Corp. have been hit hard by the new law, which immediately ended credits for about 70% of the 72 car models previously eligible for EV subsidies.

The federal EV tax credit, which is part of the new Inflation Reduction Act that narrowly passed in Congress despite widespread Republican opposition, requires many foreign automakers to produce a bigger share of their EV and battery parts in the United States to qualify for the $7,500 per vehicle tax credit.

Volkswagen maintained the tax credit for its ID.4 sport utility vehicle by shifting the assembly of the all-electric vehicle from Germany to its U.S. assembly plant in Chattanooga.

At the recent G20 summit, South Korean President Yoon Suk-yeol asked U.S. President Joe Biden to prevent discriminatory measures against South Korean companies, his office said, according to a Reuters news report.

The planned investment in Clarksville by LG Chem is the third multi-billion-dollar plant announcement this month in the Tennessee Valley. Earlier this month, Steel Dynamics announced plans for a $2.5 billion expansion of its steel production facilities near Oxford, Mississippi, to create 1,000 jobs, and last week First Solar announced plans to build a $1.1 billion manufacturing facility in North Alabama with more than 700 workers.

Tennessee Gov. Bill Lee signed a memorandum of understanding with LG Chem on Monday. The deal still awaits a sign-off from the State Funding Board, which meets again in mid-December.

"LG Chem's decision to invest $ 3.2 billion in Clarksville is a testament to Tennessee's unmatched business climate, skilled workforce and position as a leader in the automotive industry," Lee said during a signing ceremony late Monday. "What we're announcing today will change the lives of Tennesseans."

LG Chem is among more than 1,000 foreign-based companies that operate in Tennessee and collectively have invested more than $40 billion and created over 156,000 jobs, according to the Tennessee Department of Economic and Community Development.

The number of Tennesseans working for foreign-based employers jumped by more than a third in the past five years, placing Tennessee as the second fastest-growing state for employment from foreign direct investment, according to the Global Business Alliance.

"LG Chem's decision to locate its new cathode manufacturing facility in Clarksville underscores Tennessee's growing profile as a hub for U.S. and global companies," Stuart McWhorter, commissioner for the Tennessee Department of Economic and Community Development, said in an announcement of the new project. "As we continue our efforts to attract companies in the automotive industry, we are focused on supporting companies that boost Tennessee's presence in the EV space."

Tennessee is one of the top electric vehicle production states with assembly plants now producing EVs at Volkswagen in Chattanooga, Nissan in Smyrna and General Motors in Spring Hill.

Ford Motor Co. and another Korean battery maker, SK Innovation, announced plans last year to build a $5.6 billion EV assembly and battery plant in West Tennessee for the next generation of all-electric F-series trucks. The Ford plant is the largest single business investment ever in Tennessee and is projected to employ nearly 6,000 workers.

Contact Dave Flessner at dflessner@timesfreepress.com or 423-757-6340. Follow him on Twitter @DFlessner1.