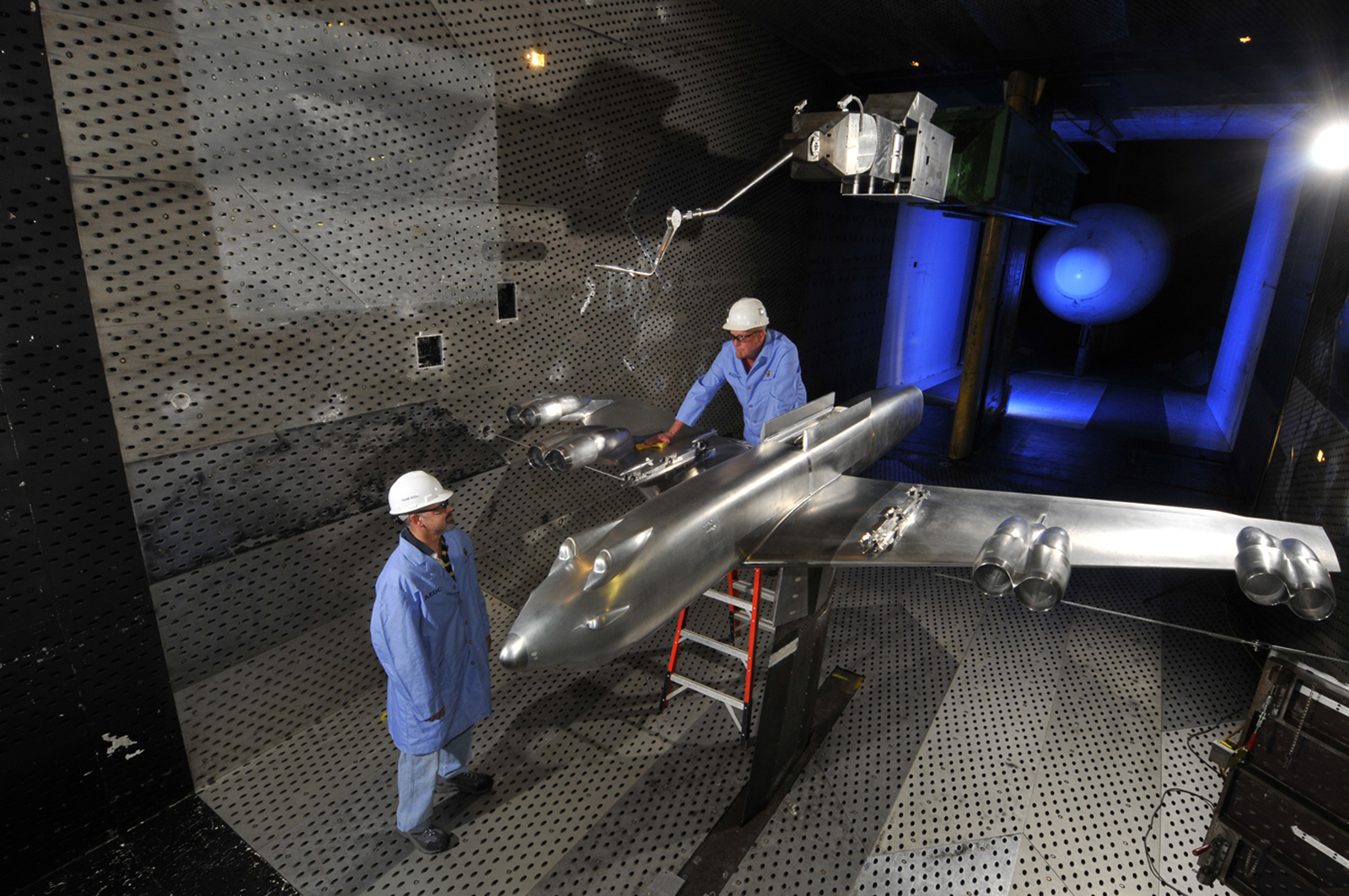

Arnold Engineering set a record for the largest aircraft model, a 10 percent scale model of a B-52 Stratofortress. The testing was requested from the B-52 Program Office to look at the scope of the internal weapons bay upgrade. From left, J.T. Thompson discusses the model with Gary Cunningham in 16-foot wind tunnel.

Arnold Engineering set a record for the largest aircraft model, a 10 percent scale model of a B-52 Stratofortress. The testing was requested from the B-52 Program Office to look at the scope of the internal weapons bay upgrade. From left, J.T. Thompson discusses the model with Gary Cunningham in 16-foot wind tunnel.ARNOLD ENGINEERING AND DEVELOPMENT COMPLEXArnold Engineering and Development Complex in Tullahoma, Tenn., is the nation's largest complex of flight simulation test facilities, dedicated in June 1951 and named for five-star General of the Air Force Henry "Hap" Arnold. The complex operates 43 aerodynamic and propulsion wind tunnels, rocket and turbine engine test cells, space environmental chamber, arc heaters, ballistic ranges and other specialized units. Twenty-seven of Arnold's test units are unmatched in the United States, and 14 are unique in the world. Facilities can simulate flight conditions from sea level to 300 miles up and from subsonic velocities to Mach 20.The facility has in its pedigree most of the military's fighters and experimental jets like the X-15, X-29, X-32, X-33, X-35 and XB-70, along with a lineup of space rockets, like the Atlas and Titan, the space shuttle, projects Mercury, Gemini and Apollo and the Minuteman and Peacekeeper ICBM missiles.Source: Arnold Engineering and Development Complex, Arnold Air Force Base

The next time you hear a sonic boom and spy one of the latest U.S. military jets streaking across the sky, you can give a little credit to some folks in Tullahoma, Tenn.

Arnold Engineering and Development Complex at Arnold Air Force Base is nearly three months into one of its busiest testing years in some time.

The U.S. Department of Defense is keeping Arnold hopping despite budget cuts to a facility that, at its peak years ago, employed about 4,500 people, officials said.

"Last week was sort of a milestone week for us," spokesman Jason Austin said Friday.

"For years, we've been staggering our tests. We would do one test in the morning and one test in the afternoon and another one the next day," Austin said. The idea was that when one plant was supporting a test, another one could not be done with Arnold's current staffing.

"But last week, we were able to run five of our engine test facilities at the same time," Austin said. "That tells you about how much work we have that we were able to figure out a way to get that work done and to do it concurrently."

In spite of budget cuts, Arnold remains one of the largest employers in its region.

"The base is a huge contributor of high-paying jobs in Coffee County and surrounding counties," Coffee County Mayor David Pennington said. Arnold is the county's largest employer.

The long-timers at Arnold -- and Austin said that's a large portion of the workforce -- have weathered a lot of shifts in activity.

"They've seen the ups and downs through the years; they know the ebbs and flows in defense budgets," Austin said. "Our peak of manpower was 4,500 people and we're down to a little over 2,000 now. There's a bit of change there."

Reductions in the workforce are hard on the workers and their families, he said, "but it's a good year this year."

Arnold this year has had a 50 percent increase in testing workload and a 25 percent increase in technology workload, according to Col. Patrick Tom, director of test operations.

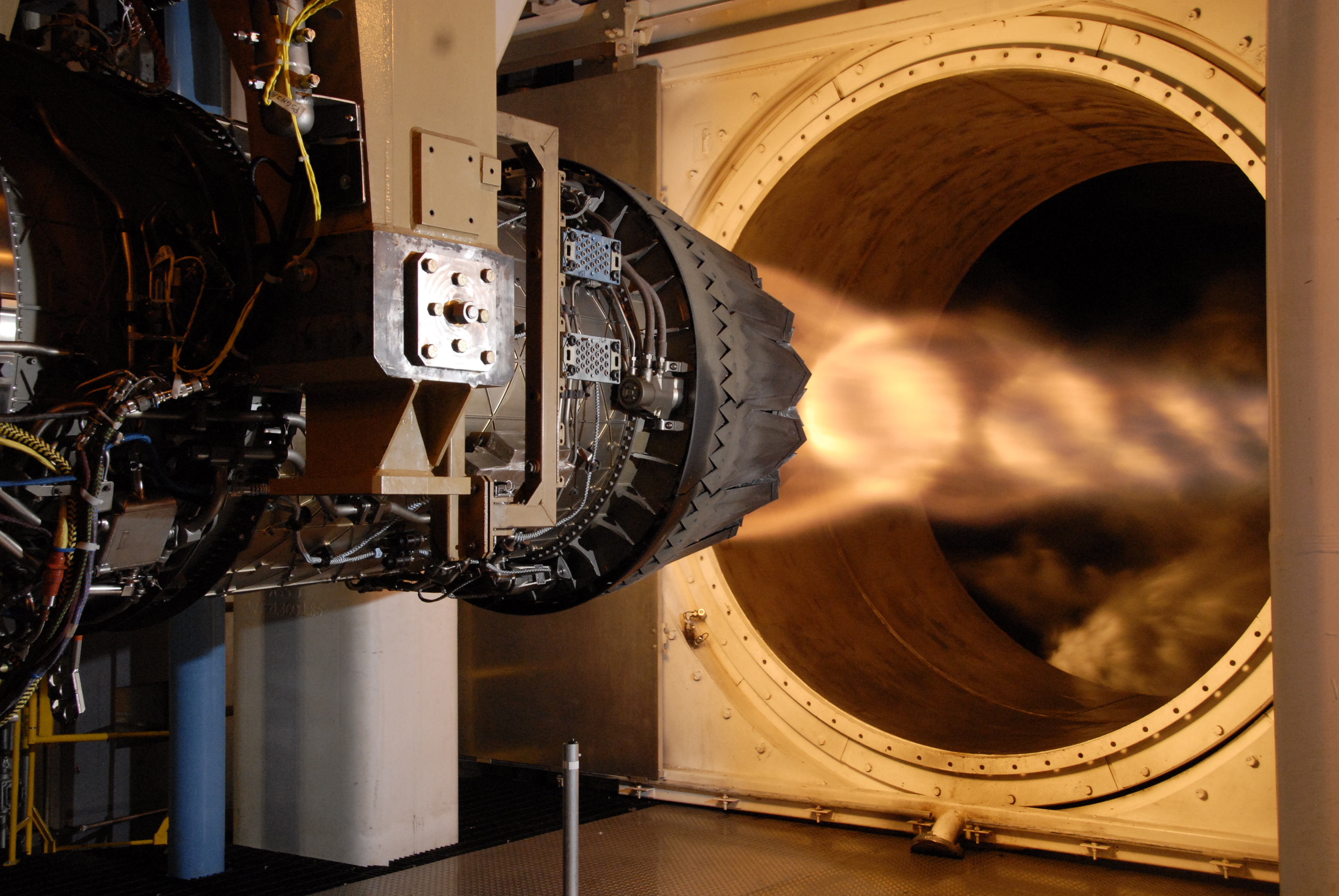

"We have engines pinned in six test cells for the first time in eight years to include engine support of the Department of Defense's priority F-22 [Raptor] and F-35 [Lightning II] fighters," Tom said a couple of months ago when testing started gearing up.

"As [defense] budgets shrink, the number of large programs may also shrink. However, there are still a large number of labs, technical demos and commercial customers who need our expertise in addition to the large, major defense acquisition programs," he said.

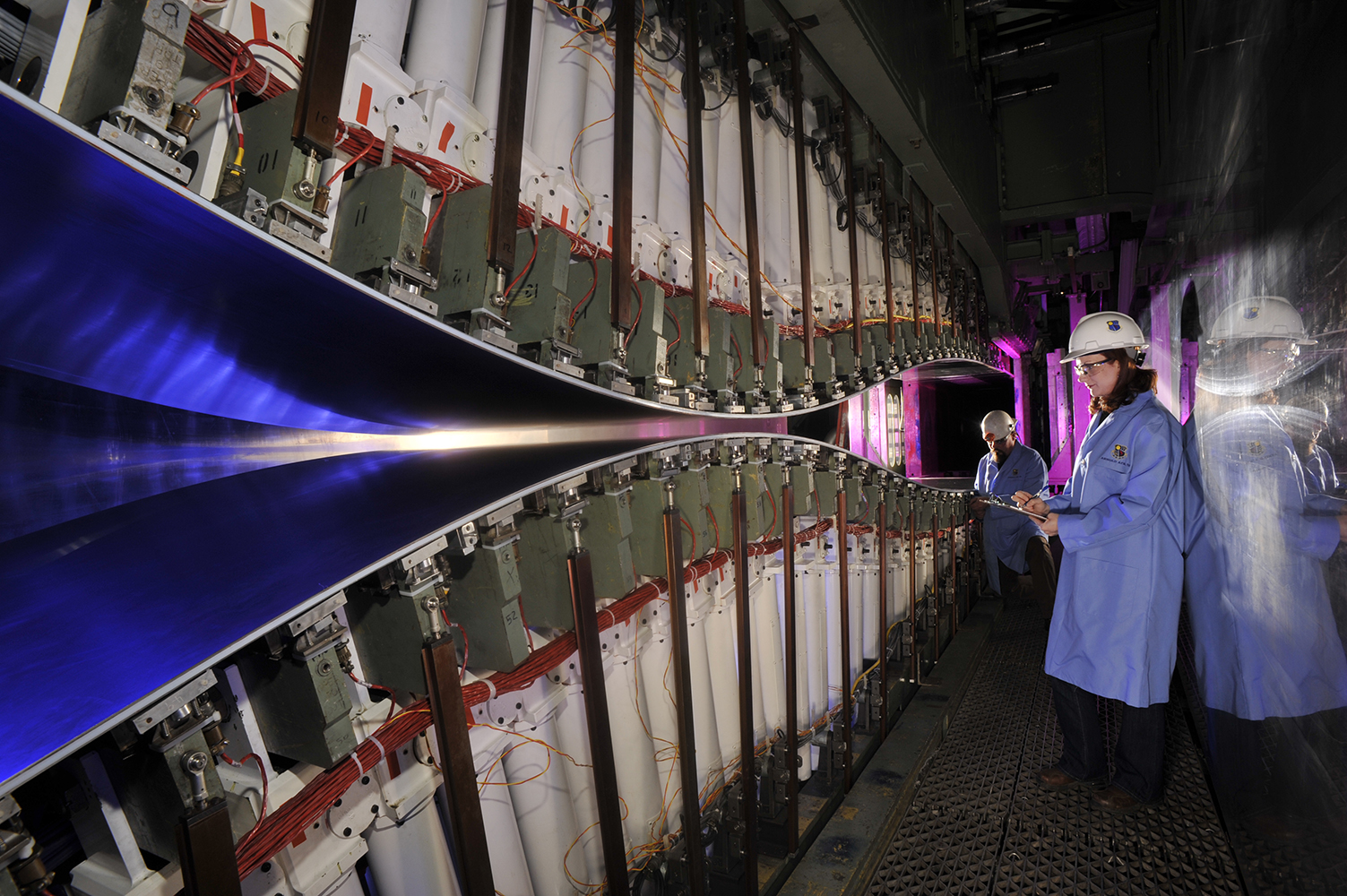

Arnold's Propulsion Wind Tunnel Facility is running three shifts, seven days a week. The wind tunnel, Engine Testing Facility, and the von Karman Gas Dynamics Facility are running at the same time for the first time in more than six years, officials said.

The vibe is certainly shaded with military secrecy at Arnold, where most of the companies and branches of service they serve are referred to simply as "the customer."

But products from those customers come with very recognizable names like the A-10 Thunderbolt II, F-14 Tomcat, F-15 Eagle, F-16 Fighting Falcon, F/A-18 Hornet and Super Hornet, F-117A Nighthawk, F-111 Aardvark, and the U.S.'s most-feared bombers -- the B-1B, B-2, B-52 and B-58.

Arnold's unique testing capabilities kept it vital even when the federal government shut down last fall.

Aerospace Testing Alliance, the primary contractor at the base, wound up in the odd position of sending workers home amid the federal government shutdown that started Oct. 1, 2013, while hiring people in anticipation of 2014's testing schedule.

That month, more than 100 people were told not to show up for work and another 300 were asked to take vacation time for a week. But by January, Aerospace Testing was back at work and hired another 35 people.

Dr. Rob McAmis, Aerospace Testing's deputy director of integrated test and evaluation, said in December that the staff was excited about the variety of testing and they like the Air Force emphasis to "own the experiment."

That concept "allows our teams to dig technically deep in the planning, execution and post-experiment assessment phase," McAmis said. "We have highly technical folks who make up our test project teams, and they excel most during times of challenge."

Tom said Arnold has "a reputation for supporting critical wind tunnels, turbines, space and missile programs."

Officials refer to Arnold as a "one-stop shop."

The facility in Tullahoma and its remote operations near Washington, D.C., in Silver Spring, Md., and in Mountain View, Calif., near San Francisco, had a $612.4 million economic impact in fiscal year 2013.

Pennington said Arnold is "really community-minded and a good partner with the [Southeast Tennessee] counties. Not only do they provide good jobs, they're good to work with."

Franklin County Mayor Richard Stewart said Arnold is neck and neck with the local Nissan plant in numbers of jobs.

"Arnold has been a mainstay for years and years," Stewart said, predicting that employment at the base probably will trend upward.

Contact staff writer Ben Benton at bbenton@timesfreepress.com or 423-757-6569.