EPB estimates its smart electric grid saved the utility more than $2.6 million in energy savings last year while cutting about 3,000 tons of carbon dioxide emissions.

EPB officials said they are now eager to use Chattanooga's advanced power delivery network to also help local businesses improve their energy efficiency and sustainability ratings.

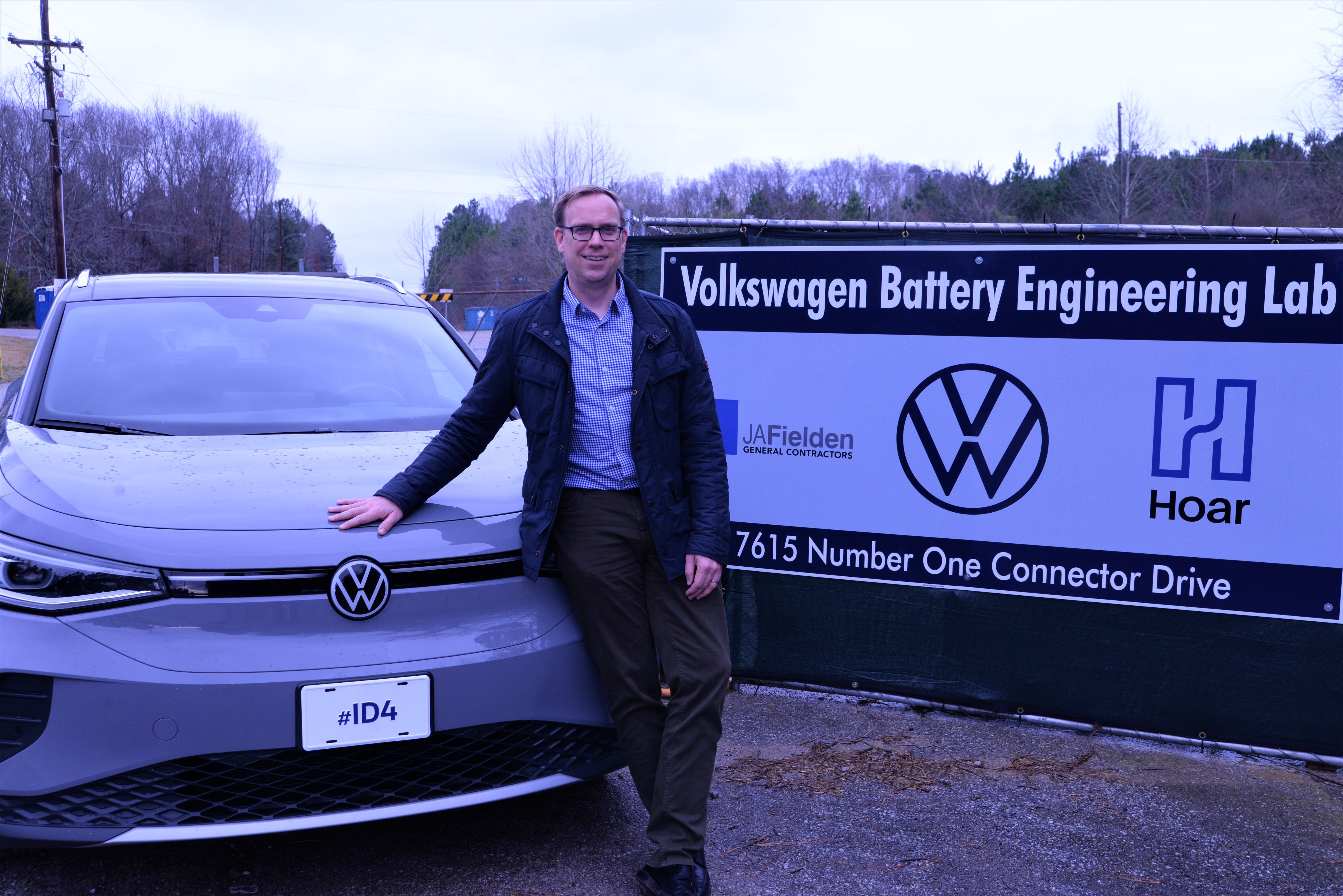

EPB, which recently was recognized by Green Business Certification Inc. (GBCI) as one the nation's first utilities to achieve Gold PEER (Performance Excellence in Electricity Renewal) status, has begun collaborating with Volkswagen of America to help the automaker also boost its environmental ratings. Volkswagen is working with EPB to achieve LEED (Leadership in Energy and Environmental Design) recognition for VW's new research and testing facility being built near Volkswagen's assembly plant in Chattanooga.

"We're building our Battery Engineering Lab with sustainable development in mind, and we're proud to team up with GBCI and EPB to facilitate the project," Wolfgang Maluche, vice president at Volkswagen's Engineering and Planning Center (EPC) in Chattanooga, said in a statement Wednesday. "This effort is part of Volkswagen's commitment to establishing more environmentally sustainable facilities in Chattanooga, where we will add comprehensive battery know-how and the localized production of electric vehicles soon, shaping Volkswagen's electric future in America."

EPB built its $220 million network of fiber-optic lines along its electric wires more than a decade ago, helping the municipal utility to build a smarter power grid to limit outages and improve energy efficiency while also offering broadband connections for high-speed internet service throughout its 600-square-mile service territory. Combined with so-called intellirupters that act like switches on a railroad track to automatically re-route power when they detect an outage, EPB has been able to reduce both outages and energy use with its smart grid.

"Through their Gold recertification, Chattanooga has achieved the most resilient and reliable PEER-certified utility power grid in the United States," Sean McMahon, vice president of product management at GBCI, said in a news release Wednesday.

The smart grid can also help monitor energy consumption on a continuous basis to help EPB customers detect problems and better limit their peak consumption when electricity prices are the highest. By shifting power use to non-peak periods, building owners and industrial power users are able to cut their power bills and improve overall energy efficiency.

"An intelligent, smart electric distribution system helps to conserve energy - with all environmental and business benefits coming along - and helps set the infrastructure foundation for future automotive engineering and production," Jonas Kulawik, head of technology communications for Volkswagen of America, told the Times Free Press Wednesday.

When Volkswagen began production at its Chattanooga assembly plant a decade ago, it was the first automotive plant in the world to be platinum LEED-certified by the U.S. Green Council. VW later built a $30 million solar array to supply about 12% of the power used at the adjacent $1 billion assembly plant.

Volkswagen's new $22 million battery lab will test and validate electric vehicle cells and battery packs and will include pressure and immersion testers, corrosion chambers, five explosion-rated climate chambers and a custom, two-ton multi-axis shaker table. The 198,000-square-foot facility is being built along Hickory Valley Road near VW's assembly plant in Chattanooga which is undergoing an $800 million expansion to make the new battery-powered ID.4 SUV and other electric vehicles of the future.

McMahon said the collaboration between Volkswagen and EPB exemplifies an important step toward becoming more environmentally sustainable.

"To ensure sustainability in our power systems, we need to go outside the building," he said. "After all, a building is only as green as the power that goes into it. Modeled after LEED, PEER addresses these needs to build in resilience, reliability and sustainable practices, which are then amplified by LEED-certified buildings, like Volkswagen's facilities, which use that power."

EPB President David Wade said he hopes other businesses will follow Volkswagen's lead and take advantage of EPB's smart grid to better manage their power consumption, reduce their carbon footprint and boost their sustainability ratings.

"We stand ready to work with other local companies and potential business investors to help facilitate their green building efforts," Wade said in a statement Wednesday. "Together, we can enhance our community's air quality and preserve its natural beauty while maintaining and creating new job opportunities."

Although such efforts reduce energy sales for EPB, especially during peak periods, they also reduce costs for what EPB pays TVA and for what Chattanooga businesses pay for electricity.

"When you sell something of value as we do, you don't want it to be wasted," Elizabeth Hammitt, director of residential energy and environmental solutions at EPB, said in a telephone interview Wednesday. "We also are a public utility that exists for the public good and these efforts are in the best economic and environmental interests of our community."

Contact Dave Flessner at dflessner@timesfreepress.com or at 423-757-6340.